Bill D

Diamond

- Joined

- Apr 1, 2004

- Location

- Modesto, CA USA

I saw an older Grob bandsaw at the used tool dealer. I think it is 18". all pulley drive with no transmission.

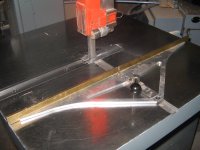

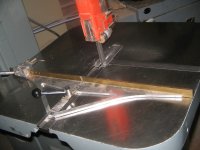

It has the normal table slot front to back to remove/install the blade. It has a solid iron strip covering the slot. It has another similar slot from the blade to the right hand edge of the table. That slot has a similar iron strip covering it but that strip has drain 1/8" holes? drilled in it all the way through. I did not really notice what it looked like at the edge of the table.

I have seen mention of a chip conveyor but that slot had no moving parts visible. Any idea what it is for? I would guess a cutting oil drain down into the base somewhere hidden away. But it seems unlikely much percentage of oil would happen to go into it.

Bill D

It has the normal table slot front to back to remove/install the blade. It has a solid iron strip covering the slot. It has another similar slot from the blade to the right hand edge of the table. That slot has a similar iron strip covering it but that strip has drain 1/8" holes? drilled in it all the way through. I did not really notice what it looked like at the edge of the table.

I have seen mention of a chip conveyor but that slot had no moving parts visible. Any idea what it is for? I would guess a cutting oil drain down into the base somewhere hidden away. But it seems unlikely much percentage of oil would happen to go into it.

Bill D