SeymourDumore,

The reason I bring up the transformer connection issue for CNC equipment, is because I encounter these types of problems regularly in my field work. Not just with metalworking CNC but also many other types of equipment that use electronic controls and drives.

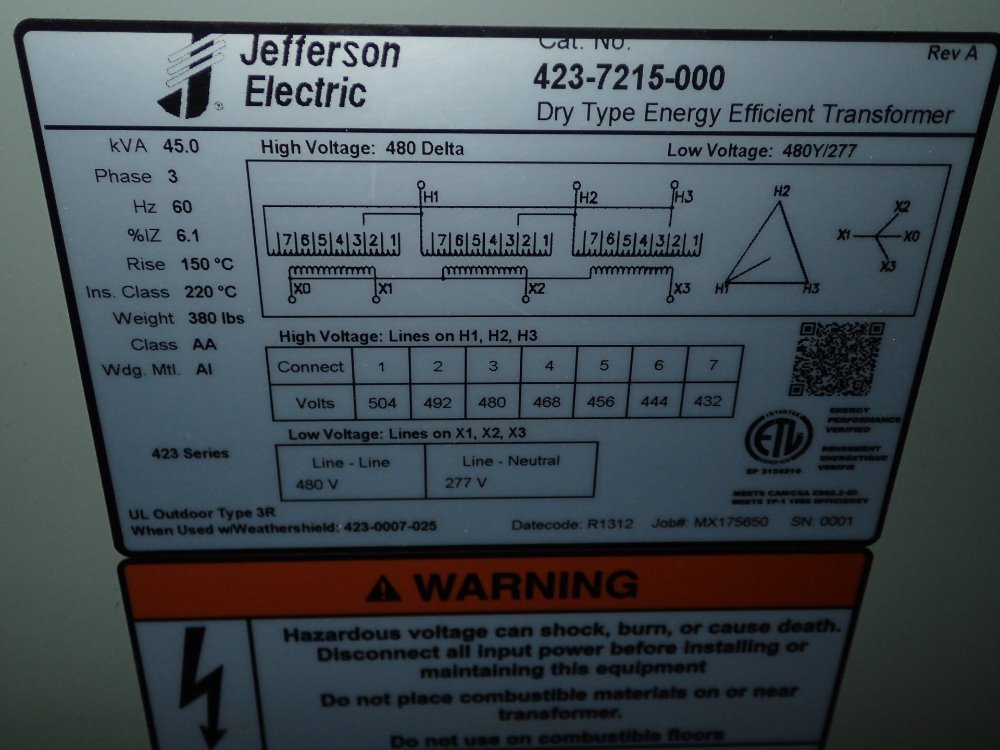

Many CNC vendors specify that the customer must provide an isolation transformer in order for the warranty coverage to be in effect. As soon as you interject a isolation transformer into the feeder to the equipment, that changes the grounding scenario. That was the subject of the OP to ground or not to ground?

Many customers and their plant service people do not understand the differences of the different types of systems, and are of the belief, that you can use any transformer that they may have handy or available used, to change the service voltage to match the equipment voltage. But ignore the requirements of bonding the output coil,to the building service electrode system, usually due to lack of understanding.

Sure, there are many types of 3Φ transformers available but the most common ones used, are for stepping down from higher voltage to lower utilization voltages. Normally delta to Y. It is when these types are re-purposed to go up in voltage, is when many run into trouble. This often happens in smaller commercial shops where the operator has a 208 or 240V service and purchases a used piece of equipment that requires 240,480 or 400V.

From my view, as far as the incoming service is concerned, all CNC equipment ( or anything else for that matter ) is a purely 3ph load, regardless of

what type of transformer is installed in them.

And, as such, the grounding is identical to all installations, that is to say a separate, dedicated conductor running from equipment all the way back to the service's ground point, regardless of where that's derived from.

I would disagree that all machine loads are purely 3Φ. Many indexing drives and other other internal equipment can be 1Φ.

I will also disagree that all grounding requirements are identical when a isolation transformer is involved. The code and good practice demands that the output coil of all isolation transformers be solidly bonded to the building electrode system for fault current and electrocution hazard prevention.

To give an example of what I'm talking about, have a gander of this recent thread, from one of the regular forum members.

http://www.practicalmachinist.com/vb/transformers-phase-converters-and-vfd/how-can-machine-ground-affect-welding-arc-325892/

He is doing things the way your suggesting. A dedicated isolated ground conductor run from the CNC equipment, to the transformer frame and on to the service equipment. He is experiencing problems of an unusual type. But unrealized to him, is that the machine frame is not bonded back to the

source of energy,

the delta output coil of his reverse connected transformer. Much worse than his welding problem, is the fact that his equipment does not have a low impedance equipment grounding connection for fault currents back to the source (isolated delta coil). This can be a serious hazard when something on the machine faults to the frame, even though the machine operates properly and is connected to the service system ground.

I come here to learn first and second to share knowledge. I can be easily persuaded to butt out, if my contributions are not welcome.

SAF Ω