ViKiNG Max

Plastic

- Joined

- Mar 15, 2022

I recently purchased a small Hardinge milling machine that has both a vertical head BB2V and a horizontal head BB4

The machine came with a small selection of imperial collets for the vertical head. From my research C (and similar) Collets these are BB2V collects with 7/16 20 drawbar. The vertical head has a different taper which from my research is 4C with 15/16 28 drawbar. I have both drawbars. What is puzzling me is that the horizontal spindle appears to have two tapers which without good measuring gear look like 10 degree per side and 5 degree per side. This is what also appears to be shown from a Hardinge publication cross section that I found on the net – marked up with a red arrow in the image. The short 10 degree taper is 4C but I have not been able to find any information on the longer 5 degree taper. I know that these machines were commonly used horizontally with a 1” arbour.

1. Are there two different tapers in the horizontal head. 4C and a different taper for the 1” arbour? If so can someone point me to specifications for 5 degree taper

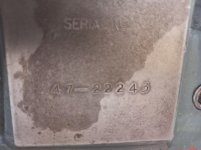

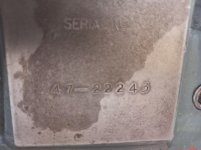

2. Can anyone please identify the age of the machine from the serial number on the horizontal head 47-22243?

3. Does the small plate on the main casting mean anything D.P.L.51. ?

The reason for the questions is that I live in a New Zealand which is metric and I am unable to use the machine until I make metric collects and 1” arbour as the collets are uncommon especially metric sizes.

The machine came with a small selection of imperial collets for the vertical head. From my research C (and similar) Collets these are BB2V collects with 7/16 20 drawbar. The vertical head has a different taper which from my research is 4C with 15/16 28 drawbar. I have both drawbars. What is puzzling me is that the horizontal spindle appears to have two tapers which without good measuring gear look like 10 degree per side and 5 degree per side. This is what also appears to be shown from a Hardinge publication cross section that I found on the net – marked up with a red arrow in the image. The short 10 degree taper is 4C but I have not been able to find any information on the longer 5 degree taper. I know that these machines were commonly used horizontally with a 1” arbour.

1. Are there two different tapers in the horizontal head. 4C and a different taper for the 1” arbour? If so can someone point me to specifications for 5 degree taper

2. Can anyone please identify the age of the machine from the serial number on the horizontal head 47-22243?

3. Does the small plate on the main casting mean anything D.P.L.51. ?

The reason for the questions is that I live in a New Zealand which is metric and I am unable to use the machine until I make metric collects and 1” arbour as the collets are uncommon especially metric sizes.