I have the inverter running, external forward - stop - reverse switch and pot. I'm trying to wire an E-Stop and it's working reverse of what I imagined (do I have wrong switch?)

I have an ABB CE4P-10R-02 switch from Galaco. Pull it out and it is open, push the button it's closed. Switch contactors I beleive are wired normally closed. There are 4 terminals on it.

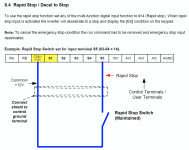

I have 03-04 set to 14, one leg of the switch is wired to common, the other leg is put into S5 terminal.

When I pull out the button, it activates the rapid stop... push it in, lets it run. I'd like it to work in reverse. Did I get the wrong switch? Is there some wiring trick I missed (I'm by no means an expert with wiring or circuits)

Any help would be appreciated..

I have an ABB CE4P-10R-02 switch from Galaco. Pull it out and it is open, push the button it's closed. Switch contactors I beleive are wired normally closed. There are 4 terminals on it.

I have 03-04 set to 14, one leg of the switch is wired to common, the other leg is put into S5 terminal.

When I pull out the button, it activates the rapid stop... push it in, lets it run. I'd like it to work in reverse. Did I get the wrong switch? Is there some wiring trick I missed (I'm by no means an expert with wiring or circuits)

Any help would be appreciated..