Photo shows- rough sawn original surface, sawed area and broken tang (brittle), Milled area, chip consistency, scale for reference. Hardness tester dents.

Thermite, it is a cutoff from a larger piece, rough sawn, looks like a coarse saw blade. it is about 7 inches long by 2 inches on the finished sides, sawed about 1/2 inch thick.

Sorry my mistake, it is only about .312" thick, definitely coarse sawn

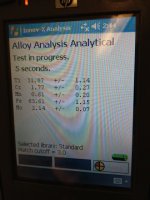

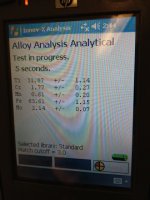

Scojen- Will do a hardness test today, I'll also surface grind and video spark. I had done a spark test and it looked like soft tool steel maybe D2 or S7 to me but I never was too good at reading a spark test, that's why I depend on the XRF.

HARDNESS 47HRC, no video but the surface grind test was weird. I don't know if anyone surface grinds titanium but after trying it years ago, I do NOT. This crap surface grinds like titanium in that it doesn't, I cannot imagine trying to surface grind this shit flat, it rubs the wheel, puts burn marks on the metal, makes a coarse surface and loads down the motor with hardly any resulting ground surface, I tried soft and hard coarse wheels, same results. The resulting spark is orange and BIG, not white like titanium but certainly a large shower of tiny orange sparks..

Mark Rand- I really think there is a problem with the test results, I don't think there is any material made with that much titanium content in it.

I MAY be mistaken! Im NOW thinking this may be some exotic sintered weird ass metal and damned if you might be right!

gbent- I agree with the weight, I compared it to a similar piece of tool steel. similar I say, the piece in question is cut off at a slight angle so I can can only approximate the dimensions, but I sure don't think there is 5/6 difference in the weight. I'll surface grind a bit of it today and have the dang thing re-tested when I can. That's an obviously good ideer!

OKAY I WEIGHED it with comparable dimensioned tool steel. Mystery metal 276g, O1 steel 307g, about the right differential, not too far from 5/6 weight difference! I was surprised, but that's no surprise. READ ABOVE to see results of surface grinding fiasco.

snowman- No the thing is not obviously coated, it does appear to have a surface on it, like a dark oxidation but not a coating, like I said the two sides are sawn surfaces. I have had things tested before with oxidation of different types and the XRF was still accurate. I guess I'll be more careful in the future. It was tested in three different locations, one on an opposite side. I just cant imagine why the results were so uniform.

Royldean- Your statement is as I understand it also, that's why I posted, weird.

THE CRAP IS BRITTLE! I thought well lets machine some of this, it saws nicely, like 416 stainless or so.I sawed a slit about .5" long with the narrow tang about .0625" wide and tried to bend it in the vise just to see how malleable it was and it broke like cast iron, no flex, just snap and broken. I milled it with a carbide endmill and it machines fine, makes chips like cast iron or Elkonite. Makes me think it is sintered.

I don't know what this crap is but at this point it is academic, I'm not going to try to use it for anything but a paperweight. If anyone wants to try to figure it out I'll certainly cooperate with answers to any questions. If you want it I'll put it in the mail, it still comes 6 days a week. I guess the bottom line is, now I think the XRF is correct and my faith is once again restored, well at least for now.

too interested to see what the material size is.

too interested to see what the material size is.