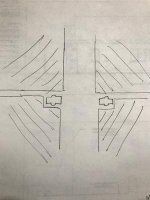

Trying to identify an oring

I was unable to find anything in the parker oring book that showed this type cross section on an oring

The one other ring not shown in the handbook we use would be a Quad ring and that is not it either

Best way to describe the cross section is rectangular with a half moon on the top and bottom

The oring does not sit in a groove, one half of the ring is open to the oil port so we do not want to try a standard ring thinking the cross section has something to do with the application

It is exposed to 2500 PSI

The supply from the OEM is getting a little slow so we are trying to stay ahead of that

Hopfully the pictures show clear enough what we are trying to locate

Thank You for any input

Greg

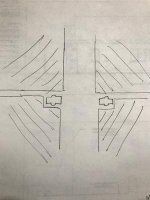

I was unable to find anything in the parker oring book that showed this type cross section on an oring

The one other ring not shown in the handbook we use would be a Quad ring and that is not it either

Best way to describe the cross section is rectangular with a half moon on the top and bottom

The oring does not sit in a groove, one half of the ring is open to the oil port so we do not want to try a standard ring thinking the cross section has something to do with the application

It is exposed to 2500 PSI

The supply from the OEM is getting a little slow so we are trying to stay ahead of that

Hopfully the pictures show clear enough what we are trying to locate

Thank You for any input

Greg