spooky

Aluminum

- Joined

- Nov 4, 2010

- Location

- West Virginia, USA

Hey All,

I'm swapping out the 3ph motor in my lathe for a single phase. I am in a temporary shop for the next year w/no 3ph access.

Per JST's sticky thread on drum switch wiring I did do a search and didn't come up with this combo

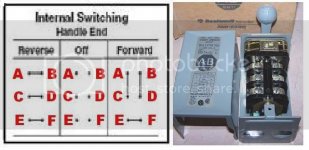

-the drum switch is a Allen-Bradley 350-TAV32. Unfortunately the schematic on the lid is too degraded to read. I tried to find one online to no avail.

-The motor is a Century C319 single phase, single voltage 220

-The motor has 2 capacitors on top. Again I couldn't find a wiring diagram on Century's webpage for this model. It is essentially a 4 wire motor (see pics below)

If anyone can help with this I'd be most grateful!

Thank you,

Chris E.

I'm swapping out the 3ph motor in my lathe for a single phase. I am in a temporary shop for the next year w/no 3ph access.

Per JST's sticky thread on drum switch wiring I did do a search and didn't come up with this combo

-the drum switch is a Allen-Bradley 350-TAV32. Unfortunately the schematic on the lid is too degraded to read. I tried to find one online to no avail.

-The motor is a Century C319 single phase, single voltage 220

-The motor has 2 capacitors on top. Again I couldn't find a wiring diagram on Century's webpage for this model. It is essentially a 4 wire motor (see pics below)

If anyone can help with this I'd be most grateful!

Thank you,

Chris E.