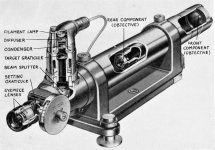

I can now answer my question from the previous post: the screws are NOT locking screws for the threaded rings. Instead, if those screws are loosened, they permit the mounted object to rotate. When tightened, they lock the rotation. This means that the target can be rotated until it is properly oriented with respect to the autocollimator body, and that the reticule can be rotated until it is parallel to the target lines.

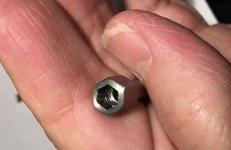

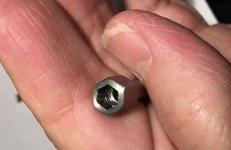

To make these adjustments, a tool is needed to loosen and tighten the locking collars. I made a tool from 8mm hex stock (free-cutting steel).

Overall length is 36mm, diameter is 5mm for the first 20mm, then 5.6mm for the next 6mm. The hole at the tip is 2.8mm diameter, and the prongs are 0.8mm wide and 0.8mm high.

I broached a 5mm hex into the wide end, so that it can be turned with a hex driver

The Id of 2.8mm at the tip is to center it on the screw, but most of the ID is 3.5 mm so that there is a bit more clearance for a screwdriver inside

This made it simple to rotate the reticule mount so that I could align the crosshairs parallel to the target. You can see that these are not perfect. If you look at the vertical parts, it appears that the reticule (outer parallel lines) is rotated slightly CCW with respect to the target (inner crosshair). But if you look at the horizontal lines, it appears that the reticule is rotated slightly CW with respect to the target. I don't know if this is optical distortion or imperfections in the target or reticule.

Apologies for the poor quality image, this is with my cell phone.

This is one of those instances where it takes a couple of hours to make the tool that is needed, and five minutes to do the actual adjustment. I'm sure that one can also buy a tool for this. The metric standard fot these threaded collars ("slotted round nuts") is DIN 546, and one can buy pronged drivers and bits for these. I'm not sure about the British Association equivalents.