Houndogforever

Hot Rolled

- Joined

- Oct 20, 2015

- Location

- Boring

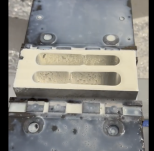

I have an aluminum 6061-t6 part. It is 1-1/2" x 3" and 8-1/2" long.

Standing on edge, I mill the part to 2.875 tall, then mill a 1" step down across most of it.

At the bottom of that step is a 3/4" wide slot going down from the edge of the tall square end to the opposite end.

This requires a 1" stick out PLUS the 1-3/4" depth of slot leaving me with a tool hanging 2-3/4" +.

I've been running this is a Fadal with a long 5/8 3 flute hog mill taking steps down but I'm not too sure of running a long 5/8 endmill in old speedy.

So how would you guys rough out the big slot?

Standing on edge, I mill the part to 2.875 tall, then mill a 1" step down across most of it.

At the bottom of that step is a 3/4" wide slot going down from the edge of the tall square end to the opposite end.

This requires a 1" stick out PLUS the 1-3/4" depth of slot leaving me with a tool hanging 2-3/4" +.

I've been running this is a Fadal with a long 5/8 3 flute hog mill taking steps down but I'm not too sure of running a long 5/8 endmill in old speedy.

So how would you guys rough out the big slot?