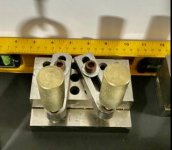

This block was made and used by a man who was the TDM for a major appliance manufacturer for 40 years. Block weighs 15 lbs, 4 x 6 x approx. 2.3 inches. I have very little grinding experience but bought it because I’m starting to use surface grinders and may need this one day. Posting because I’ve never seen anything like it, may give someone ideas.

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Interesting grinding block

- Thread starter Cannonmn

- Start date

- Replies 5

- Views 1,254

eKretz

Diamond; Mod Squad

- Joined

- Mar 27, 2005

- Location

- Northwest Indiana, USA

Looks like he might have used it for squaring ends.

Mebfab

Diamond

- Joined

- Jun 7, 2003

- Location

- Mebane North Carolina USA

An old friend of mine worked at a huge injection molder in the toolroom. Mold repairs and such. Long periods of nothing to do. Free material, unbelievable shop full of equipment, full heat treat dept.

To keep busy (and look busy) he made some pretty impressive hardened and ground angle plates, V blocks, squares, etc. Betting the same thing here.

To keep busy (and look busy) he made some pretty impressive hardened and ground angle plates, V blocks, squares, etc. Betting the same thing here.

michiganbuck

Diamond

- Joined

- Jun 28, 2012

- Location

- Mt Clemens, Michigan 48035

Looks like a combination squaring block and vise, with it having movable/setable clamps and hold-down options.

*I think it could be very handy.

A good chance the screw points are on greased stubs so they might tighten with not twisting the held part.

One might also have/make a block like that or an angle plate to be used with a parallel clamp with it (the parallel clamp) having screw clearance holes in the parallel clamp jaw, so it might be stationed in the needed place...so one part and the next might be located in a precise way.

I used to run special tool bits that way with a compound tilt angle plate. It might take 10 minutes to get the exact position..and then you can run a big number of parts at perhaps 2 minutes each for that one feature.

*I think it could be very handy.

A good chance the screw points are on greased stubs so they might tighten with not twisting the held part.

One might also have/make a block like that or an angle plate to be used with a parallel clamp with it (the parallel clamp) having screw clearance holes in the parallel clamp jaw, so it might be stationed in the needed place...so one part and the next might be located in a precise way.

I used to run special tool bits that way with a compound tilt angle plate. It might take 10 minutes to get the exact position..and then you can run a big number of parts at perhaps 2 minutes each for that one feature.

AD Design

Stainless

- Joined

- Jun 27, 2012

- Location

- Tennessee USA

To keep busy (and look busy) he made some pretty impressive hardened and ground angle plates, V blocks, squares, etc. Betting the same thing here.

-That's what I did for the same reasons. Any palm sized drops from tool steel I had to cut for die components were future tooling. Many small vises, angle plates, and assorted tooling became fill in projects to fill the idle hours.

Similar threads

- Replies

- 10

- Views

- 327

- Replies

- 6

- Views

- 621

- Replies

- 10

- Views

- 1K

- Replies

- 34

- Views

- 5K

- Replies

- 9

- Views

- 985