EddyCurr

Aluminum

- Joined

- May 22, 2009

- Location

- Edmonton, AB. Canada.

An acquaintance has a K.O. Lee S618HG hydraulic surface grinder. The machine is in nice condition, but seals for the cylinders that power longitudinal and crossfeed table travel leak excessively.

The acquaintance tells me he is faced with having seals made to order.

Are suitable cylinder rebuild components (possibly in kit form) available for the OEM cylinders?

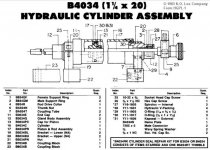

From "Parts List And Instruction Book For S618HG" (HGPL-1 1983) by KO Lee Company

The acquaintance tells me he is faced with having seals made to order.

Are suitable cylinder rebuild components (possibly in kit form) available for the OEM cylinders?

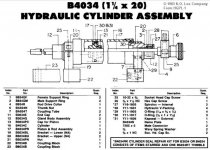

From "Parts List And Instruction Book For S618HG" (HGPL-1 1983) by KO Lee Company

** === B4034 (1-1/4 x 20) Hydraulic Cylinder Assy

4 pc - #28 Y11-1601 V-Packing

4 pc - #29 Y11-1903 O-Ring (1/16 x 3/8 x 1/2)

3 pc - #30 Y11-1917 O-Ring (1/8 x 1 x 1-1/4)

1 pc - #31 Y11-1606 Kapseal - External

** === S234 Cylinder Crossfeed

2 pc - #22 Y11-1601 V-Packing

3 pc - #23 Y11-1922 O-Ring (1/8 x 1-3/4 x 2)

1 pc - #24 Y11-1608 Kapseal - External

** === S434 Cylinder Crossfeed

4 pc - #22 Y11-1601 V-Packing

3 pc - #23 Y11-1922 O-Ring (1/8 x 1-3/4 x 2)

1 pc - #24 Y11-1608 Kapseal - External

1 pc - #26 01W100-28-4 Seal (S334)

4 pc - #28 Y11-1601 V-Packing

4 pc - #29 Y11-1903 O-Ring (1/16 x 3/8 x 1/2)

3 pc - #30 Y11-1917 O-Ring (1/8 x 1 x 1-1/4)

1 pc - #31 Y11-1606 Kapseal - External

** === S234 Cylinder Crossfeed

2 pc - #22 Y11-1601 V-Packing

3 pc - #23 Y11-1922 O-Ring (1/8 x 1-3/4 x 2)

1 pc - #24 Y11-1608 Kapseal - External

** === S434 Cylinder Crossfeed

4 pc - #22 Y11-1601 V-Packing

3 pc - #23 Y11-1922 O-Ring (1/8 x 1-3/4 x 2)

1 pc - #24 Y11-1608 Kapseal - External

1 pc - #26 01W100-28-4 Seal (S334)