beckerkumm

Hot Rolled

- Joined

- Aug 5, 2014

- Location

- Wisconsin Rapids WI

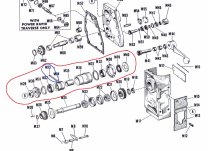

I'm embarrassed to admit that after five years, I'm finally getting back to the Monarch 60. The lead screw attaches to the gearbox with a bearing cartridge with two bearings. I know the bearings should oppose each other and I think the end with the narrow outer shoulder should face out on each end. That way when the bearings are pressed in, the balls push against the outer shoulder and don't fall out. ( Don't ask how i know this )

The cartridge has a loose inner spacer that sits between the bearings and there is an outer specer on the gear end and an oil seal on the end with the flange that bolts to the gearbox. I would like someone to verify the bearing direction is correct and if there is any other advice. Thanks, Dave

The cartridge has a loose inner spacer that sits between the bearings and there is an outer specer on the gear end and an oil seal on the end with the flange that bolts to the gearbox. I would like someone to verify the bearing direction is correct and if there is any other advice. Thanks, Dave

. But maybe the pics will help in some way.

. But maybe the pics will help in some way.