Tom A

Hot Rolled

- Joined

- Apr 26, 2009

- Location

- NW Florida

In the first stereo photo, I can see that big Pond drill (Like the one in the catalog), in the middle background - What a beast !

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

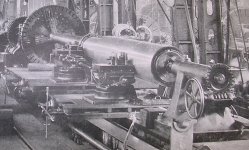

Bethlehem Steel Company, Bethlehem, Pennsylvania. 91 inch diameter corrugated ingot in cutting-off lathe. It looks like the parting tool could be 12" tall.

1.

1.

Cool photo! check out the rag tied onto the steady, most likely there to oil the turned diameter that is riding on the steadies pads.Here is the link to the high resolution copy of the cutting-off lathe.

In the first stereo photo, I can see that big Pond drill (Like the one in the catalog), in the middle background - What a beast !

It was the one with the curved frame - I guess the other one was so huge, I didn't even recognize it as such! Either would be too big for my shop, I think :~)If you are talking about the stereo photo in post #178, there are two drills in the photo, both are New York Steam Engine Co. ones.

Rob

It was the one with the curved frame - I guess the other one was so huge, I didn't even recognize it as such! Either would be too big for my shop, I think :~)

That would have been a heartbreaker if that was scrapped - The table isn't even scarred up .....Seeing old machines like that in scrap yards reminds me of this:

Not really sensitive. An early screw feed drill.That's a beautiful old drill in that photo - It looks like it's specially made for fine, "sensitive" work, as I don't see a lever or anything for coarse feed, just that geared hand wheel. It seems a big drill, for that sort of work.

Notice

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.