Ray Behner

Diamond

- Joined

- Mar 27, 2009

- Location

- Brunswick Oh USA

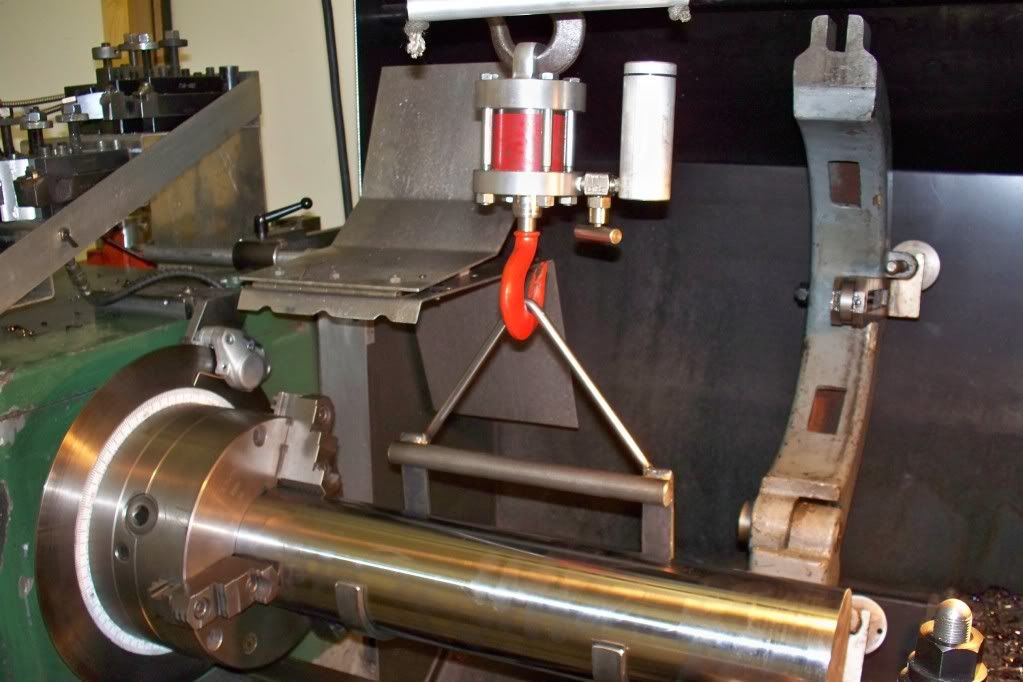

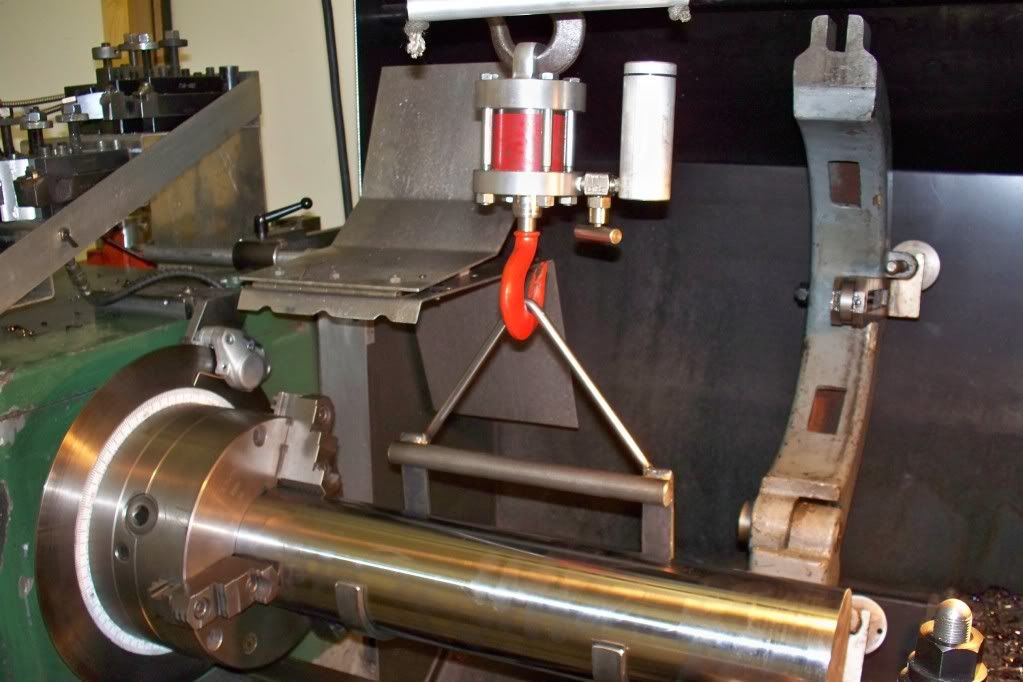

I've got an overhead hoist on rails with an electric chain hoist attached. Tough to regulate the stopping of it, so I made this little cylinder with a needle valve to slowly let the piece down to the chuck and steady without a bang. Also nice for aligning the chuck to the spindle.

Ray

Ray