Selfmade

Plastic

- Joined

- Jun 12, 2005

- Location

- Deutschland

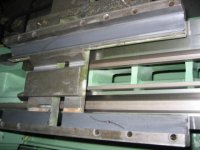

Last week I bought this lathe from a German dealer. It's a Lorch B30LZ hight precision lathe from 1975. It is in a very good condition and the dealer gave me a lot of tools surplus.

The next month, I beginn to recondition the lathe, so that it looks like new.

Best regards

Günter

The next month, I beginn to recondition the lathe, so that it looks like new.

Best regards

Günter