Isak Andersson

Aluminum

- Joined

- Nov 3, 2021

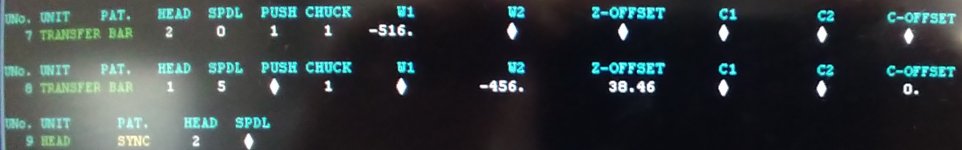

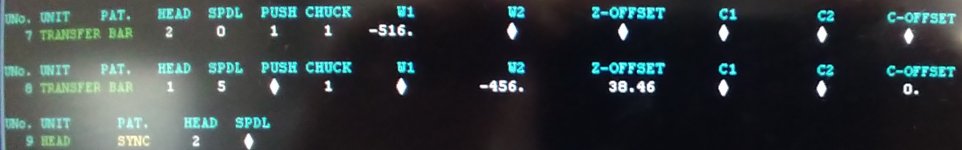

Hello. This is a weird problem I can't really make sense of. When I use the main spindle as master during synchronous rotation, everything works as expected but when the sub-spindle is selected as master the offset changes by about -500 mm. Is this a programming error on my part? A parameter? What's going on here?

The reason I ask is that I have been getting a Spindle Controller Malfunction alarm when using the main as master. I wanted to try using the sub as master to see if this makes a difference.

The reason I ask is that I have been getting a Spindle Controller Malfunction alarm when using the main as master. I wanted to try using the sub as master to see if this makes a difference.