Peter S

Diamond

- Joined

- May 6, 2002

- Location

- Auckland, New Zealand

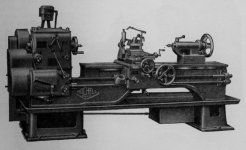

Another lathe in NZ, similar to the last photos above and also a similar design to the Graham & Normanton-made Mitchell's, but less levers on the feed/threading box.

FWIW, the photos in the last few posts have been chosen to show variations of name (and possibly maker).

Most of the surviving Mitchell of K. lathes in NZ are different (later?) than the ones shown so far.

FWIW, the photos in the last few posts have been chosen to show variations of name (and possibly maker).

Most of the surviving Mitchell of K. lathes in NZ are different (later?) than the ones shown so far.