lathehand

Cast Iron

- Joined

- Jan 31, 2005

- Location

- San Francisco Bay Area

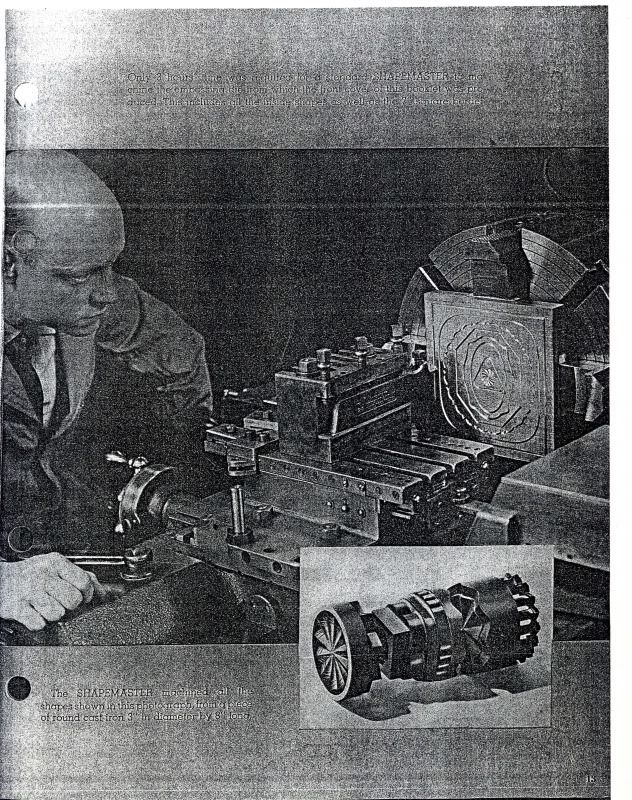

Monarch Lathes built the Shapemaster to machine bottle molds etc. I have a memory of seeing a photo of a Coke bottle mold but no memory of the lathe.

I have an active thread on the Antique Machinery forum about the Blanchard gunstock lathe and the many uses of the principle of the copying lathe. Ries posted a note about the Shapemaster and I'm posting the queston here. Does anyone have further information on this machine? I think it probably not a copying (Blanchard type) lathe.

TIA

Carl

I have an active thread on the Antique Machinery forum about the Blanchard gunstock lathe and the many uses of the principle of the copying lathe. Ries posted a note about the Shapemaster and I'm posting the queston here. Does anyone have further information on this machine? I think it probably not a copying (Blanchard type) lathe.

TIA

Carl