The Current FADAL that you can buy and get parts for...

https://www.fadal.com/images/specsheets/4020B-II.pdf

has a 10,000 rpm spindle with 175 ftlbs (

as it's geared) and has 15 HP (

peak - output).

Their 15,000 rpm spindle has 220 ftlbs of torque (geared) and has peak HP output of 22.5 HP

I certainly get the appeal of geared spindle mills for LOW end torque, - even for low HP machines that has been a great advantage for 70 years at least.

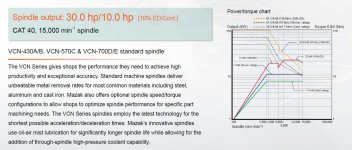

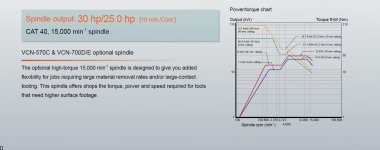

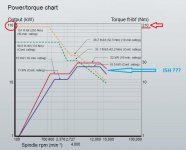

Very different from MAZAK's general "Jam" of integrated spindles and inline spindles.

I'll do the spindle curves for MAZAK 15K RPM two different spindles in a following post - just for clarity. FWIW lol ;-)

lol you can call it a 10 horse power spindle if you like. Even though peak horse power is 25 hp and 29.5 hp ...

BUT your FADAL's low end torque (geared) for what you want to do is awesome -

175 ft lbs. that's what matters and

where on the curve of course. + rigidity being helpful.

The machine the EZ mill can "Dooooo" a 4th axis BUT - in general MAZAK unfortunately don't want "Peeps" to slap on a two rotary axis trunion (5 axis unit) to a three axis mill, ~ you CAN- or used to (like 15 years ago) but the machine becomes pretty dedicated to that with cablings and wiring and plumbing becomes a pain in the arse to undo - So That's why they (MAZAK) are more into "Upselling" folks on dedicated 5 axis machines. :-( / :- /

A lot of techs at MAZAK for in house training have to learn ALL the machines rather than have more time on a particular platform like Mill turn integrex or Variaxis etc. Usually they complain that they can't spend more time on a particular platform or line that they like. Maybe in the mind of the disaffected individual demo-ing the machine he or she feels they drew the "Short straw" - whereas HAAS are very proud of what their VF line can do ? [Food for thought really.].

If the guy standing at the machine is basically saying "It won't cut for sh*t" (paraphrasing a near imaginary conversation) then that IS worth paying attention to, assuming they don't start whiffling on about financing and VCN 530C etc.

That's interesting; the HAAS UMC 750(s) had a heavy door but they redesigned it.

So you moved the door back and fourth and it was heavy / stiff or awkward ? Maybe the gauge thickness is helpful ? (safety ?) lol.

View attachment 322352

^^^ Click to big-ulate.

So ^^^ Options, 1000 psi, rotary options, niagra coolant , enhanced filtration etc. etc. blah.

The T foot print does make the machine bed casting look freakishly narrow from the front profile, in spite of being taller / rigid.

I personally like the 41" table height but that's not for everyone (for sure).

___________________________________________________________________________________________________________

@Ianagos I certainly get or get the vibe that you are not taken by the EZ machine at all / very unimpressed. esp. for around $100K.