I have been brought up on CAM too, I have never programmed a machine with conversational programming and wouldn't know where to start with it either, I've always used Inventor and now Fusion 360. So if EzGuide is basically only for conversational programming, then I will save the money and not get it. I've only used Doosan / DN lathes, not a vmc, but have used other brand vmc's ( not Fanuc ).

What exactly is the MEM card - do I buy that from the dealer or separately myself from Fanuc or somewhere?

One of the main reasons I'm looking at the DEM is because it is the largest machine ( table travel ) that I can fit in my garage - the garage door height being the limiting factor. The only other options in my neck of the woods seems to be a Haas, or a Syil X7, but they have their problems too, mainly no support on the ground, it's either Facebook groups or go through China every time. They also don't do that machine with a Fanuc, only LNC, 22MA, or Siemens. A Syil X9 might fit but I can't find the height yet as the machine still hasn't been released properly yet, they do this with a Fanuc, but the total lack of support and problems people are having with their X7's worries me.

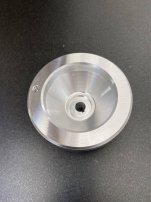

Here is a "lathe" job in more ways than one. (It is a replacement handwheel for the lathe tailstock at the high school. A student broke the original. Don't ask... I did not form the keyway using the DEM.)

Here is a "lathe" job in more ways than one. (It is a replacement handwheel for the lathe tailstock at the high school. A student broke the original. Don't ask... I did not form the keyway using the DEM.)