Congratulations on the new machine.

I bought the same machine recently. I got brother's support table with built in clamps. I haven't used it so far.

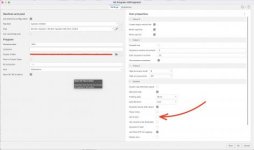

View attachment 334519

View attachment 334520

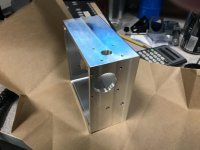

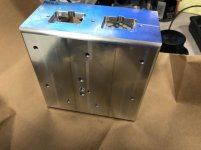

I made some adapter plates for 52 Quick Point vises.

View attachment 334521

I found the dimensions are not as intended but they hold the vise within +- 0.04ish mm from actual position. Part of the reason is that I was not (and still not) measuring cutter diameter. I used values right from the label e.g. 6mm, 10mm etc. I am considering buying V anvil micrometer or radius measuring tool setter. And another thing I found was Z height also varies depending on if spindle is warmed up or not and it is not a small deviation (might be close to 0.1mm or so). I recently activated TDC and need to look into how to use it properly.

Anyways, as the centre of the vise is slightly misaligned with the centre of rotation in both Z and Y, Rotary Fixture Offsets would have be ideal solution. Since the centre of rotation is known (170mm in Z and -200mm in Y) and X is pretty easy to measure, I can set them to G54, etc and then set G54.2 P?? on the part. I should take care of the misalignment and tract the WCS with the rotation of 4th.

But I have no idea how to work with them in Fusion 360. Spent some time on forums and found no solution. Finally I thought let's just try outputting program. I used proper "Tool Orientation" for each tool paths and went ahead with Post Processing. Selected "Use A" in the NCCode window, it outputs program without any error. There is nothing in the program to rotate 4th.

Then I tried changing var useMultiAxisFeatures = true (default is false);

This outputs the code with G68.2 (Feature Coordinate System) and then G53.1 (Feature Coordinate Index). I spent close to a week reading about G54.2 and G68.2 and how to get fusion 360 to output them only to find out that I don't have these options installed on the machine. They are paid options.

Only option at this point is to have Workpiece Zero Points for all rotations which is very time consuming. I think it will be better to do 3 axis setup in 2 operations rather than machining all sides and then touching up for WCS in all orientations.

Even if I go ahead doing that, still no idea how to get rotations from Fusion 360 post without splitting into multiple setups (in Fusion 360) and post them out separately and then manually add G0 A?? and call appropriate programs.

I am curious how are you going to program for the 4th axis especially in Fusion (If I am not mistaken you are using Fusion 360?).