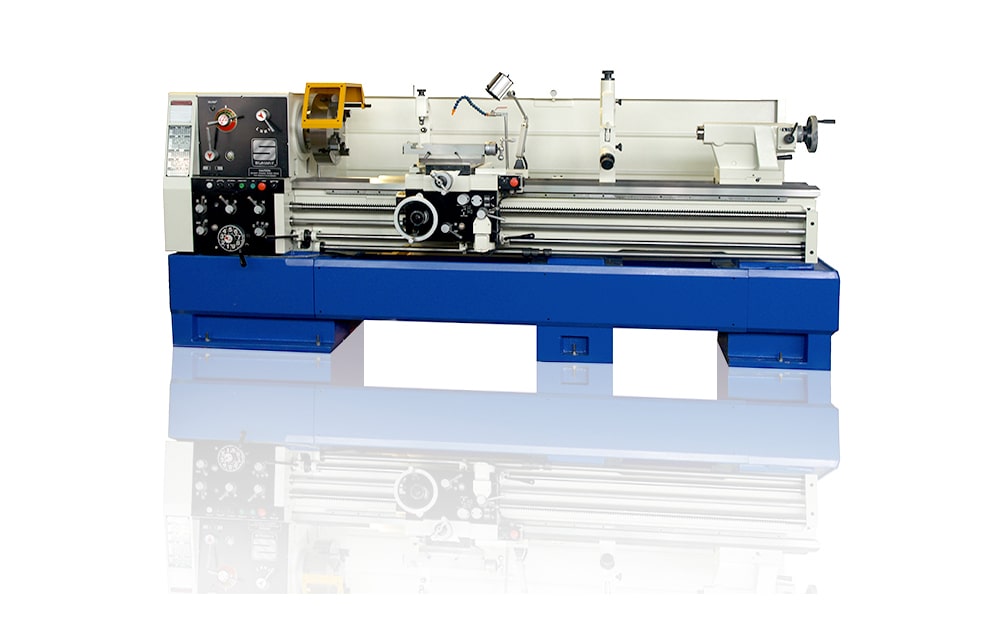

I will preface that I have been reading older postings related to this topic but want to ask about a specific machine that I have not found discussed but am open to other options. Our shop is looking to possibly replace one of our current manual lathes. We currently have 5 older lathes 2 of them are 10" south bend, a toolroom sized do-all, a Clausing engine lathe, and a large Chinese lathe. All of the current lathes are older and show wear but the Chinese lathe is in the worst condition. This lathe has a spindle bore of 4.25" and we use the through spindle bore one a regular basis with 4" material. The lathe is rather large and not extremely user friendly which is somewhat understandable because of the overall size, but we need to replace it and would like to have something new that could also serve the purpose of being our primary lathe that we also use for smaller diameter jobs.

1. I know that usually a 1 tool fits all generally does not do all jobs great it does all jobs "OK"

2. We must have a through spindle bore of over 4"

3. Current bed length from chuck to the end of the bed is 78". We do not use the full length on a frequent basis but it is always nice to have the length but don't really need longer.

4. Current considerations are Weiler lathes. Do not want to really go with the Asian market as far as Chinese or Taiwanese (would consider others like Japanese). Was considering the CNC/manual capabilities of a Weiler E series. Pros? Cons? Is it better to go strictly manual lathe and keep all CNC operations on our CNC machines? We do have old timers that still strictly run manual in our shop and they would probably be the primary users. Are there other European or US based manufactures that you would consider.

5. To go a different route, if we were to replace one of our smaller engine/toolroom lathes if there is not a good 1 size fits all what brand would you go with? Weiler? Other European/US manufacturer?

I know that this is an extremely broad question, but wanted some outside input. Also the vast majority of the work we do is sub 2" but we have to keep a large lathe on hand. If there is not a good 1 size fits all that you have experience with we would probably opt to replace one of the smaller lathes.

Thanks in advance.

1. I know that usually a 1 tool fits all generally does not do all jobs great it does all jobs "OK"

2. We must have a through spindle bore of over 4"

3. Current bed length from chuck to the end of the bed is 78". We do not use the full length on a frequent basis but it is always nice to have the length but don't really need longer.

4. Current considerations are Weiler lathes. Do not want to really go with the Asian market as far as Chinese or Taiwanese (would consider others like Japanese). Was considering the CNC/manual capabilities of a Weiler E series. Pros? Cons? Is it better to go strictly manual lathe and keep all CNC operations on our CNC machines? We do have old timers that still strictly run manual in our shop and they would probably be the primary users. Are there other European or US based manufactures that you would consider.

5. To go a different route, if we were to replace one of our smaller engine/toolroom lathes if there is not a good 1 size fits all what brand would you go with? Weiler? Other European/US manufacturer?

I know that this is an extremely broad question, but wanted some outside input. Also the vast majority of the work we do is sub 2" but we have to keep a large lathe on hand. If there is not a good 1 size fits all that you have experience with we would probably opt to replace one of the smaller lathes.

Thanks in advance.