I recently picked up a lathe I had been wanting for quite some time, a Monarch 10 EE, it was manufactured 06/1962 and is a square dial machine. I was told it would run on single phase 220v. When I went to pick it up, they wired it up to 3 phase 220v and it ran well. I had been told it was supposed to have a max speed of 4000 RPM, but would max out around 1800 RPM. It seems like it had a higher RPM when I ran it prior to getting it loaded when I picked it up, but after I got it home it doesn't seem to go any faster than 1800 RPM. Initially I did wire it to single phase 220v and it ran, but ended up wiring it up to 3 phase 220v to see if that would make any difference in RPMs, but it didn't.

View attachment 325769 View attachment 325770

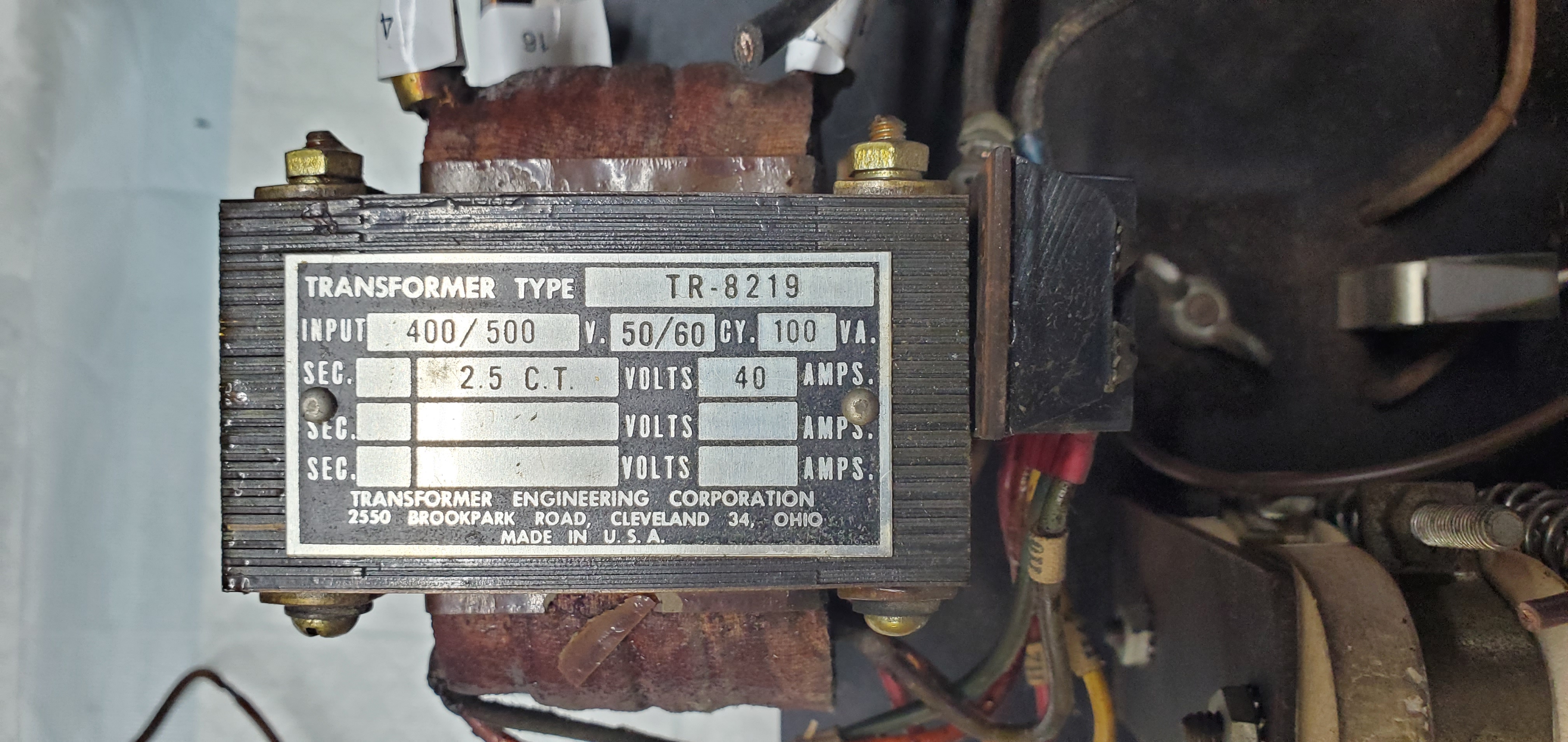

Most things work as they should as far as I've been able to tell with exception of the max RPMs, although it seems there is an issue with the dynamic breaking. I decided to open up all of the various compartments to look at things and see if I can see anything obvious which needs addressed. Well...

View attachment 325772 View attachment 325773

View attachment 325772 View attachment 325773

So it appears I need to replace some wiring. But...I'm not sure how I'm going to be able to replace the wire which leads to the top of that tube?

As always, I am open to comments, suggestions, or ideas.