pompeiisneaks

Plastic

- Joined

- Aug 20, 2021

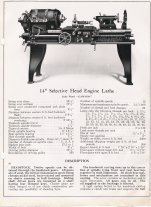

I have a Lodge & Shipley 20" lathe from the 1925 era. (I've had the machine dated via the serial number stamped on the ways). Monarch doesn't support that old of a lathe. Wondering if anyone has any details on the parts/components like drawings or service manuals? I think I have all the parts but not 100% sure. I'm starting the cleanup as it was in a garage for who knows how many years collecting dust and a bit of rust. I might have to scrape the ways and slide back in, not sure at this point, but that's all new to me, but am willing to take on the challenge to restore this old beast. It also has an old GE motor on it 3 phase at 440 VAC, 7 1/2 HP but has details on it how to rewire it for 'lower voltage' I'm guessing/hoping that's about 220 or so. I might be able to get the old model number off the plate of the motor but it's a bit dirty still so I'll have to clean it up. Any information people have would be great. I do know of vintagemachinery.org and I found a doc that seems to be perfect for this timeline and it has a few images etc, but no closeups or detail on the parts themselves. Just overview shots.

Posting a few pics of the old beast.

Thanks!

~Phil

Posting a few pics of the old beast.

Thanks!

~Phil