newtoid1986

Plastic

- Joined

- Nov 13, 2011

- Location

- Sussex, UK

Hi guys,

I've got 120 stainless parts to turn with a 1/8"-27 NPT female thread. I've been given a tap specifically for stainless.

I want to be nice to the tap so I'd like to vote an internal taper before tapping.

Online data tells me to drill first 8.4mm.

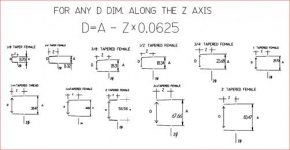

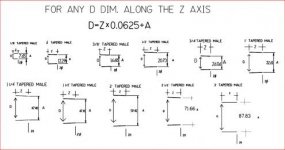

My question is what taper angle do I machine and how deep?

The 8.4 hole can be through the 20mm long part.

Thanks in advance

I've got 120 stainless parts to turn with a 1/8"-27 NPT female thread. I've been given a tap specifically for stainless.

I want to be nice to the tap so I'd like to vote an internal taper before tapping.

Online data tells me to drill first 8.4mm.

My question is what taper angle do I machine and how deep?

The 8.4 hole can be through the 20mm long part.

Thanks in advance