Terry Harper

Cast Iron

- Joined

- Sep 3, 2009

- Location

- Maine USA

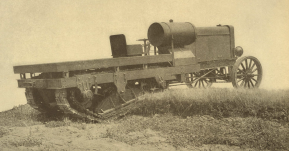

Well... yet another adventure begins! Back in July Paul and I spent a wonderful day awakening his circa 1919 Lombard tractor from a long slumber. This particular machine was salvaged from a remote site near Glazier Lake in far, far northern Maine back in the 1960's by the late John Connors. John also had acquired the remains of sister Lombard that had been cutup and the engine used to power a sawmill. In 1991 Paul and his brother Ray acquired the complete chassis and remains and began the restoration. Completed in 1996 it had sat dormant for the last 26 years.

What makes this beast unique is its the oldest surviving, intact Lombard tractor. As such it has quite a few unique features including a brass radiator surrounds as opposed to cast. A really neat gear shift where the lever actually slides sideways and what appears to be a massive flywheel mounted Hilliard clutch as opposed to the later transmission mounted Lombard unit. However, what really sets this machine apart is the engine which is the original Sterling Model FT. As far as we know this is the only surviving example.

A big six cylinder T-head with a bore of 5-1/2" and a 6-3/4" stroke (962 cid) Designed in 1915 by the Sterling Engine Company of Buffalo, NY. it is based on their model "F" marine engine. It features a fully counter balanced crankshaft and a crazy full pressure lubrication system using an oil pump that is actually three pumps in one (a scavenge pump drawing from each end of the oil pan and a service pump). It also has dual ignition via a magneto and an Atwater-Kent "Unisparker" (distributor) and dual plugs. To say its a high quality engine would be an understatement. I am confident it would put even a Locomobile T-head to shame. While its only rated at 145 hp @ 1,500 rpm its just massive torque. When the governor kicks in your going over or through whatever is in the way. You don't just hear this engine - you feel it! Its also a very smooth running engine.

Anyway, before I arrived Paul had done quite a bit of prep-work - setting up a temporary gas supply, installing new battery cables etc. After a bit of frustration we found out that the condenser in the magneto was long past its goodness date. After swapping out the magneto and fiddling with setting the timing along with a healthy does of gas through the primer cups and the beast rumpled to life. Since it is setup with skis and Paul wasn't willing to sacrifice his blueberry bushes we couldn't go far with it. This Spring it will be moved to the Maine Forest & Logging Museum. We will give it some TLC and hopefully have it out and about during future winter events.

Here is the video:

Daylight for the first time 26 years. Yes, I new seat is top of the list!

What it looked like before the restoration:

Since the engines were identical, Paul and Ray used the complete engine that came from a Lombard that had been cut-up to power a sawmill.

What makes this beast unique is its the oldest surviving, intact Lombard tractor. As such it has quite a few unique features including a brass radiator surrounds as opposed to cast. A really neat gear shift where the lever actually slides sideways and what appears to be a massive flywheel mounted Hilliard clutch as opposed to the later transmission mounted Lombard unit. However, what really sets this machine apart is the engine which is the original Sterling Model FT. As far as we know this is the only surviving example.

A big six cylinder T-head with a bore of 5-1/2" and a 6-3/4" stroke (962 cid) Designed in 1915 by the Sterling Engine Company of Buffalo, NY. it is based on their model "F" marine engine. It features a fully counter balanced crankshaft and a crazy full pressure lubrication system using an oil pump that is actually three pumps in one (a scavenge pump drawing from each end of the oil pan and a service pump). It also has dual ignition via a magneto and an Atwater-Kent "Unisparker" (distributor) and dual plugs. To say its a high quality engine would be an understatement. I am confident it would put even a Locomobile T-head to shame. While its only rated at 145 hp @ 1,500 rpm its just massive torque. When the governor kicks in your going over or through whatever is in the way. You don't just hear this engine - you feel it! Its also a very smooth running engine.

Anyway, before I arrived Paul had done quite a bit of prep-work - setting up a temporary gas supply, installing new battery cables etc. After a bit of frustration we found out that the condenser in the magneto was long past its goodness date. After swapping out the magneto and fiddling with setting the timing along with a healthy does of gas through the primer cups and the beast rumpled to life. Since it is setup with skis and Paul wasn't willing to sacrifice his blueberry bushes we couldn't go far with it. This Spring it will be moved to the Maine Forest & Logging Museum. We will give it some TLC and hopefully have it out and about during future winter events.

Here is the video:

Daylight for the first time 26 years. Yes, I new seat is top of the list!

What it looked like before the restoration:

Since the engines were identical, Paul and Ray used the complete engine that came from a Lombard that had been cut-up to power a sawmill.

Last edited: