Ox

Diamond

- Joined

- Aug 27, 2002

- Location

- Northwest Ohio

It was a dark and stormy night....

My shop did not start as a planned venture. I was actually employed by a [not so old] classmate and fellow dumb farmer in his stamping shop that he started while still finishing high skewl. I hired in a cpl yrs later and built die blocks and ran the grinders for the most part.

My first week on the job was 98 or 98-1/2 hrs and eventually got cought up enough that I werked my way down to 5-12's. I racked up prox 5000 hrs in a yr and a half. While I didn't expect to make a million overnight being a newbie in the game, my pay was not escalating hardly a'tall, and coupled with being [nearly] the only tool box in the shop with the lowest pay I got pretty upset one day when I had to stand 3 deep in line to git in my toy box behind one guy making half aggin more and the boss. At that point you hafta stand back and ask "What am I dooin?"

Eventually something put me over the edge and I ended up at the end of one day grabbing a forktruck and loading my toybox in the truck. I came into werk the next day with a mill wrench and a calculator. At the end of the day we came to an agreement I guess.....

It would seem that 1989 was NOT a boom yr, although we at that shop were always swamped - but you'll have that at eny business on the way up eh? I thought that I could find something somewhere quickly enough. .... Wasn't to be. A chumm that had heard that I was sleeping late called up and said that another fella had quit and they had an opening at the gas station as a pumper/wrench if I was interested. ... Well why not, it's better'n nut'n...

Aboot that same time a feller that I was building some benders and such for at the old shop had also heard that I was not there enymore. Him and the old boss had had some confrontations a while back and had split ways already. He was thinking on puting in a mill and such and maybe hiring me on if I was interested? ...Beats dealing with the public! (gas station) Well it seems that his wife put the cabosh to that! But he said that if I was interested in buying my own equipment - he had enough werk to git me started. Well for this dumb farmer - that's quite an invitation if ever I heard one!

I was shopping for equipment days and werking the gas station 2nd shift for a while. I doo remember one day for sure that I was a cpl hrs late to werk (I called in) as my day had been longer than hoped, but I had a $400 Kalamazoo saw in the back of the truck! After a few weeks I was up and running and quit the gas station and was back at the long hours once again. I had been away from the shop for prolly less than 2 months, and I was surprised how quickly the trade had seemed to slip from me. I had to stop and think aboot things that had been routine just a cpl months ago. But soon it was all back and now I had to doo design as well as build. I was up for eny challange - I was 22, single, and had nothin' to lose!

After a few weeks I was up and running and quit the gas station and was back at the long hours once again. I had been away from the shop for prolly less than 2 months, and I was surprised how quickly the trade had seemed to slip from me. I had to stop and think aboot things that had been routine just a cpl months ago. But soon it was all back and now I had to doo design as well as build. I was up for eny challange - I was 22, single, and had nothin' to lose!

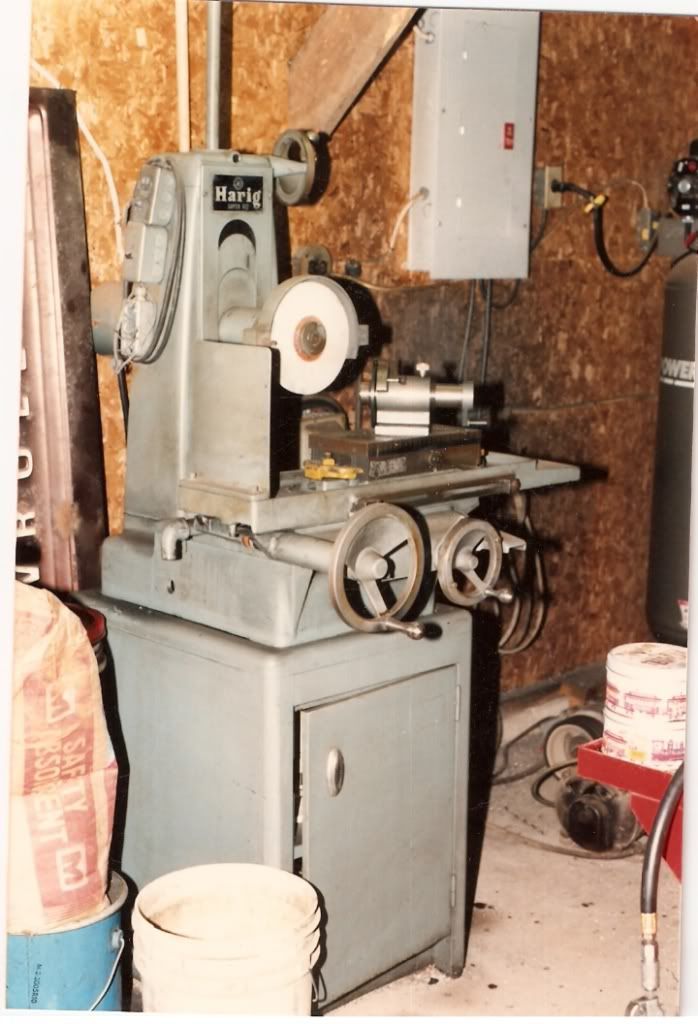

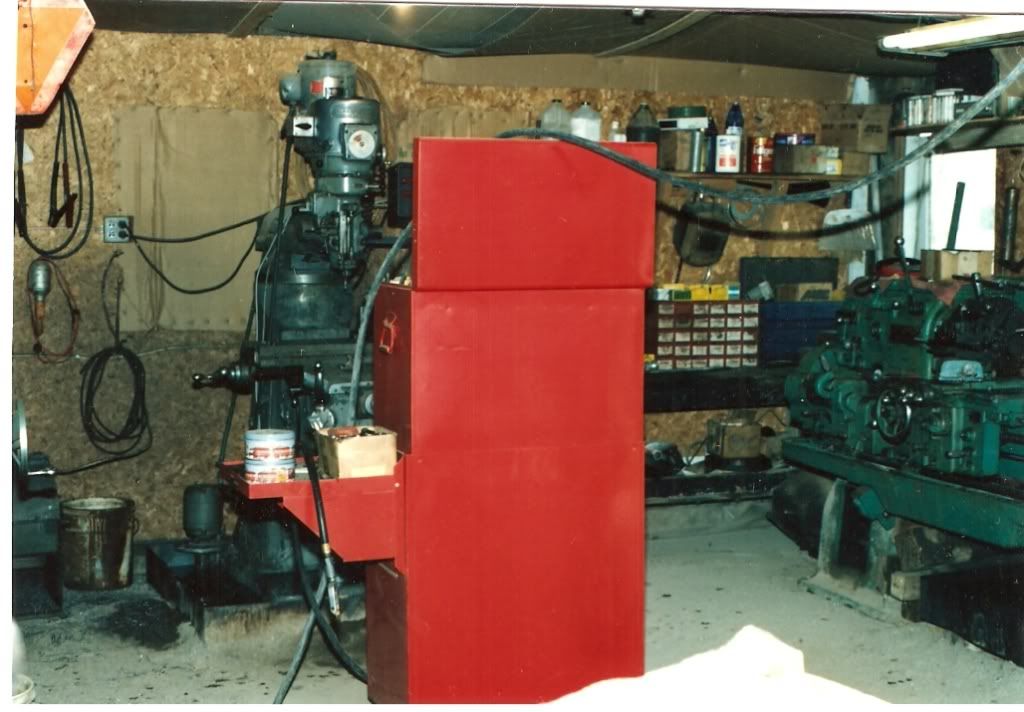

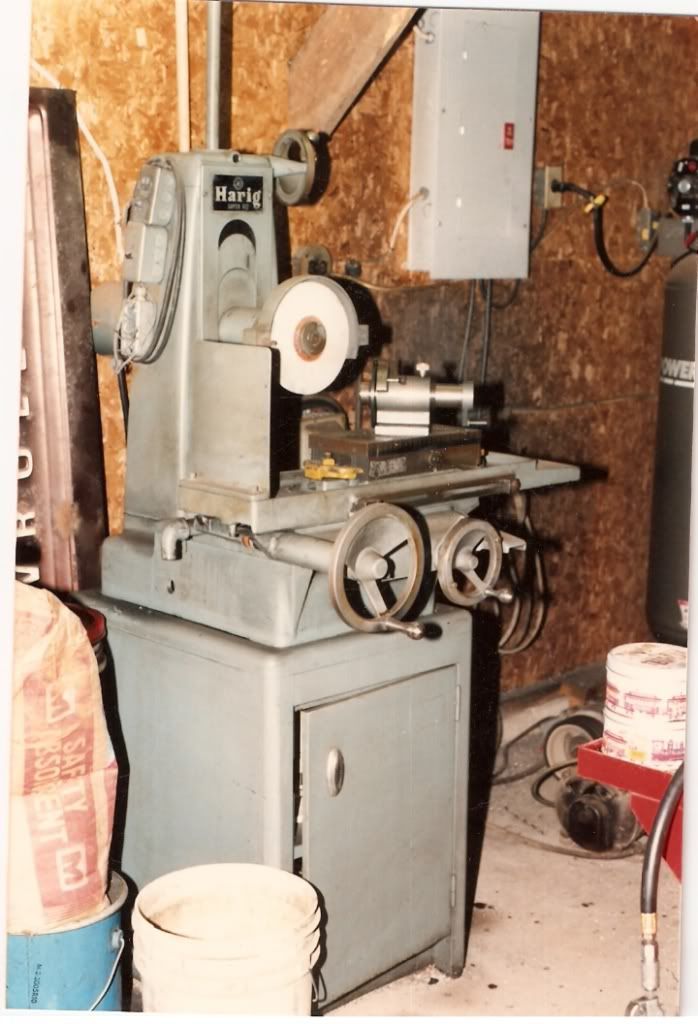

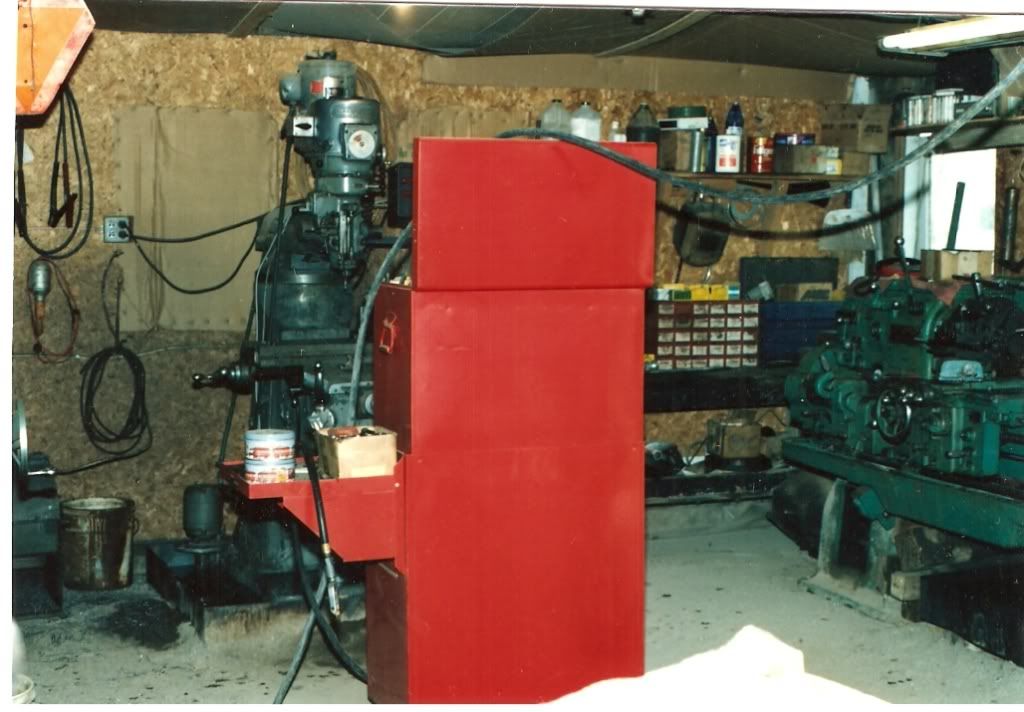

I started with a mill, grinder, kick start phase convertor, and an air compressor. I had essentially no experience on a lathe and so I didn't rank that high on my needs list and decided that I could just farm out that for now. Within 6 months tho - I had decided that I could easilly make payments on a lathe with all the $ that I was farming out - and found a 16x36 LeBlond from the war.

I did not see the machine run, and found out when I got it hooked up that the main power shaft had been sheared off somehow. ??? OK, so now I got the machine apart and have two power shafts and all I really need is one. What's a feller to doo? I thought that they looked like they could simply be faced true and actually be bolted back together. So what - take it to a shop with a "werking" lathe? I didn't have that kinda $. Keep in mind that I am a 22 yr old broke plowboy. I have been werking on my own in many regards for many yrs. I quickly came up with a plan! Chuck up the shafts in the lathe and sspin the chuck by hand and fix it... and that's exactly what I did! I had the machine for maby 15 more years and I NEVER had another issue with that (or any others that I can think of) shaft!

I had the machine for maby 15 more years and I NEVER had another issue with that (or any others that I can think of) shaft!

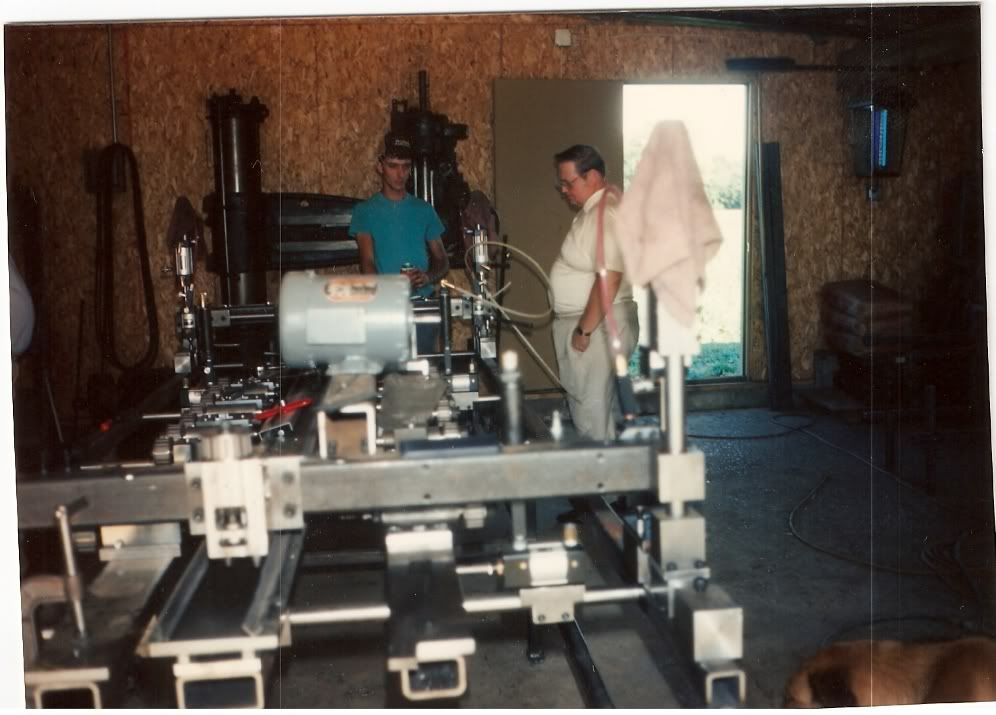

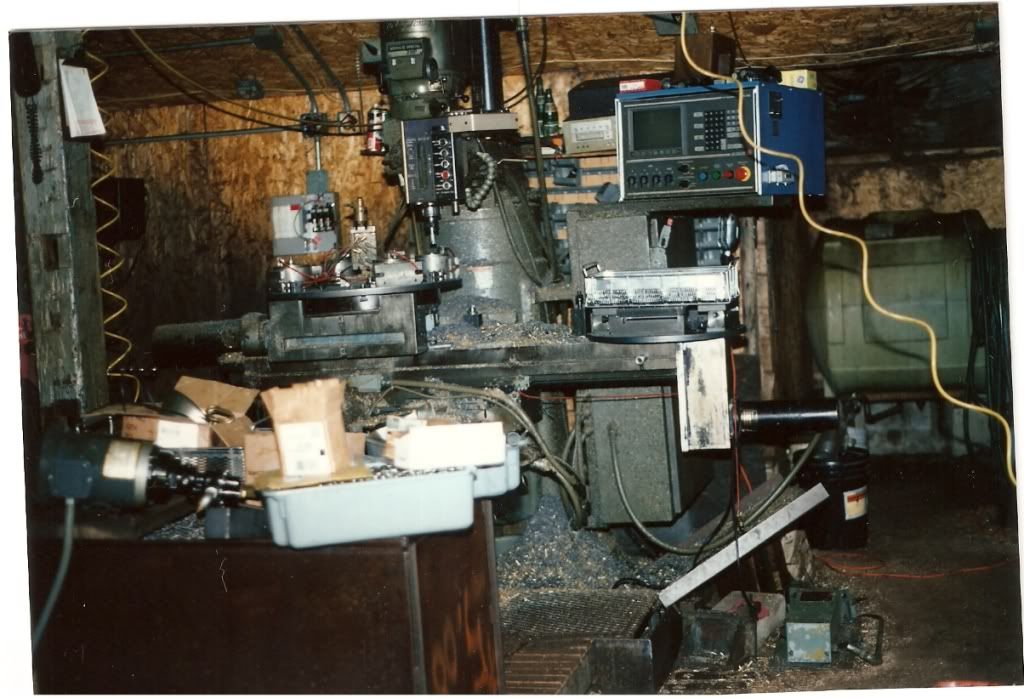

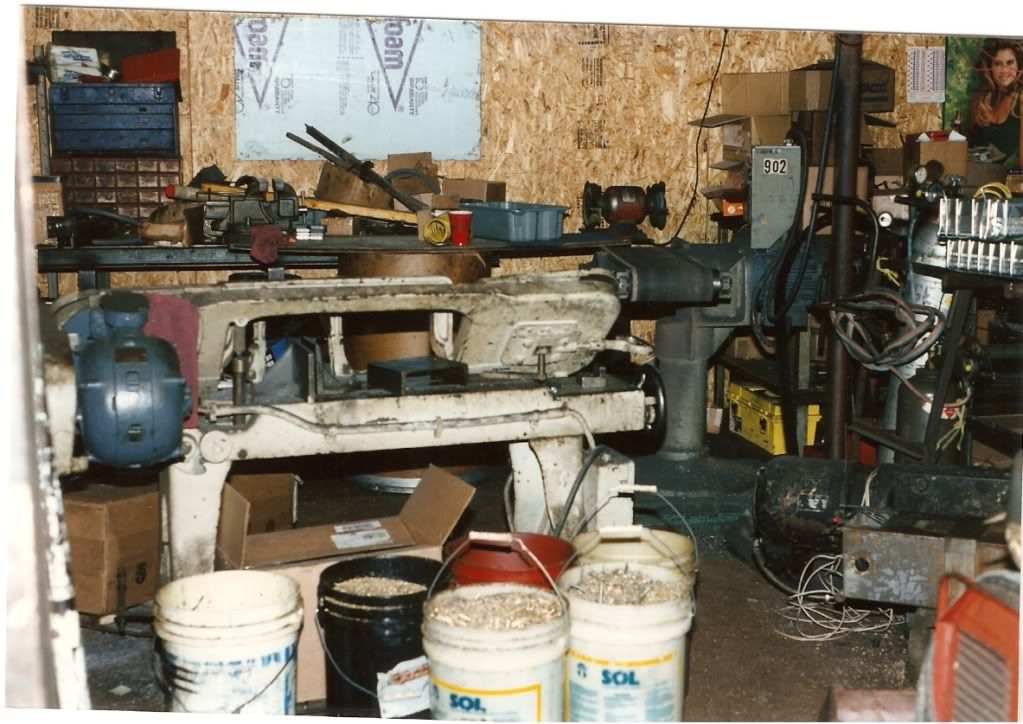

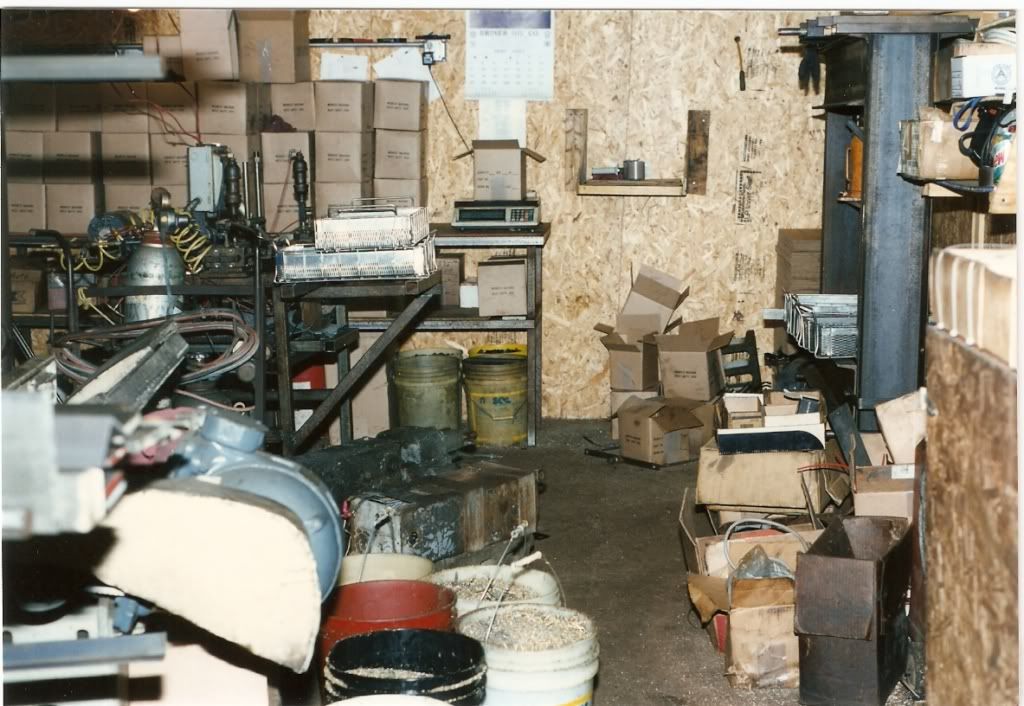

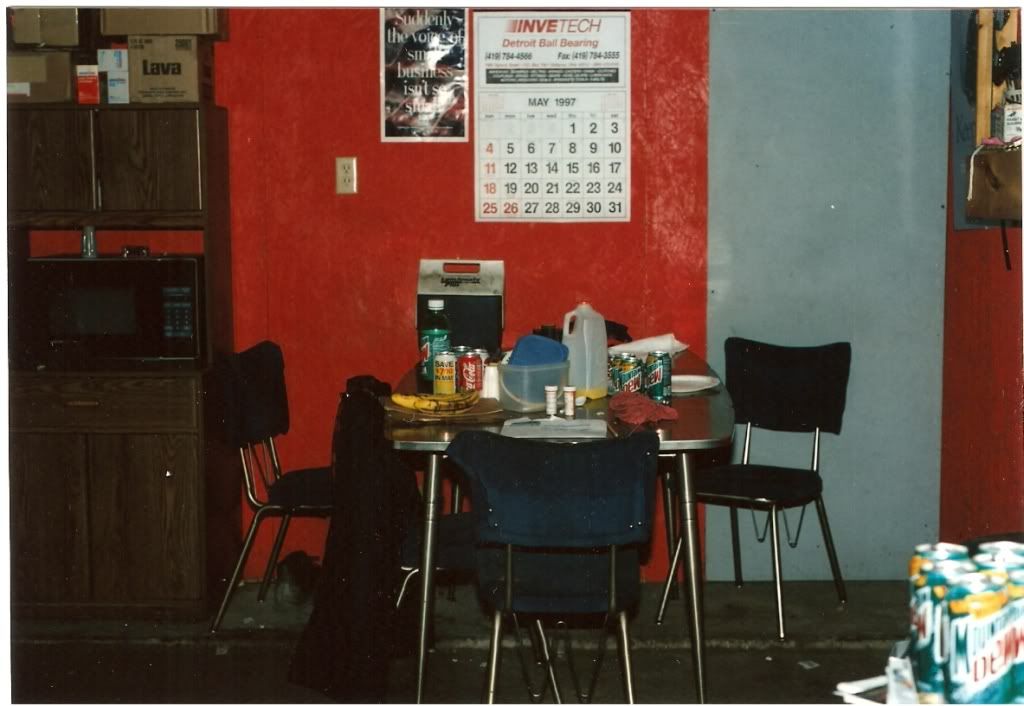

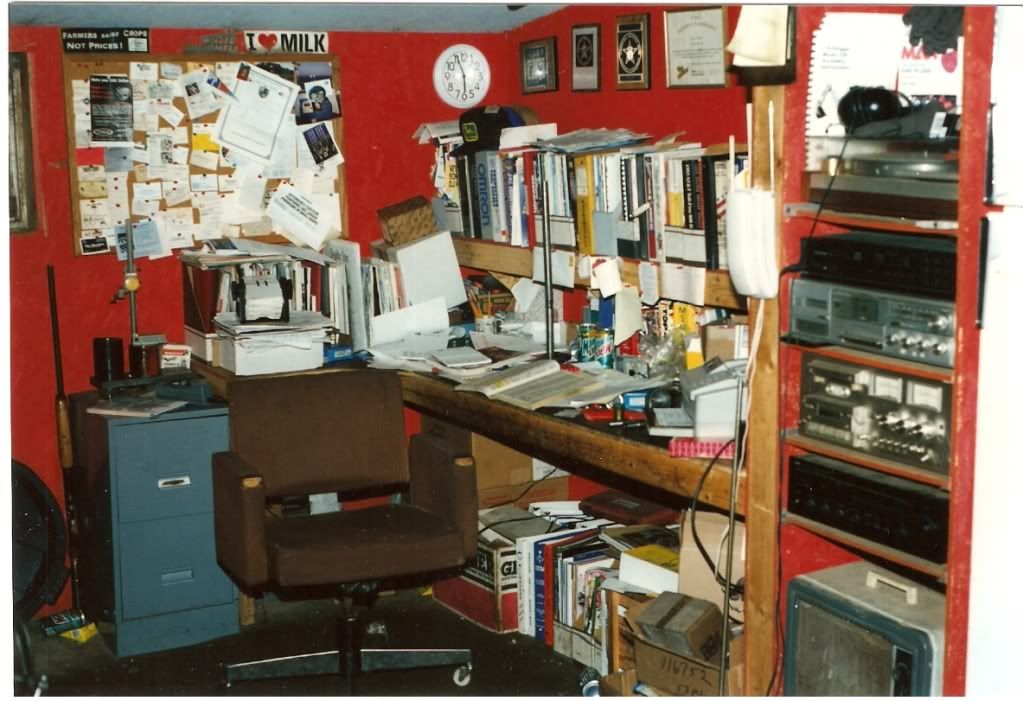

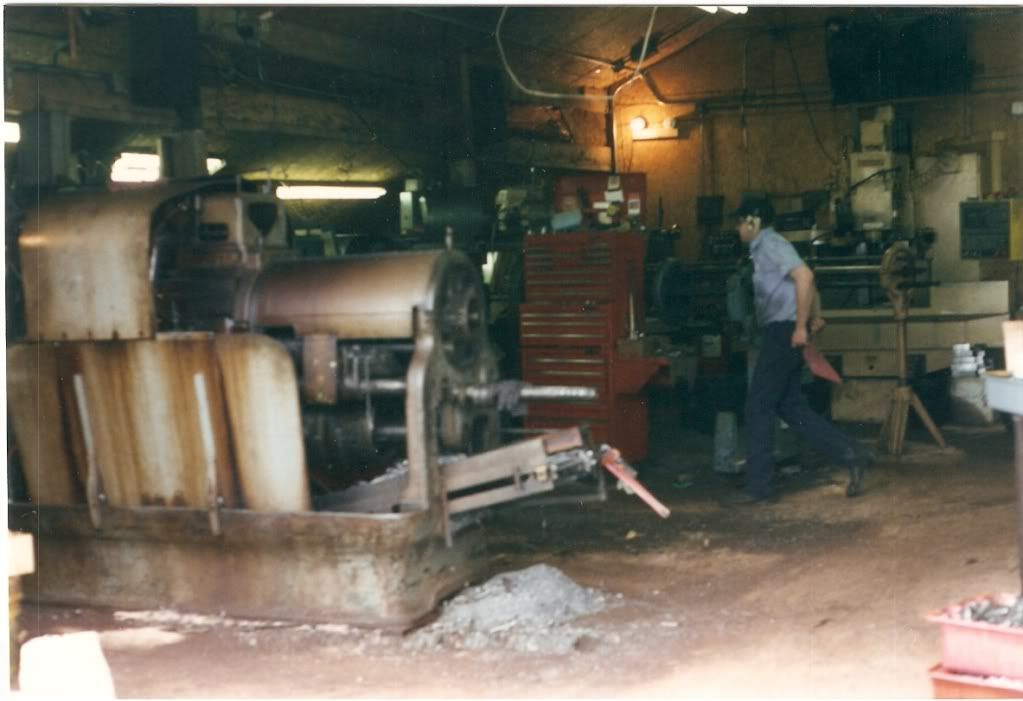

These pics are from "Stage 1" which could also be referred to as a 1-1/2 truck garage.

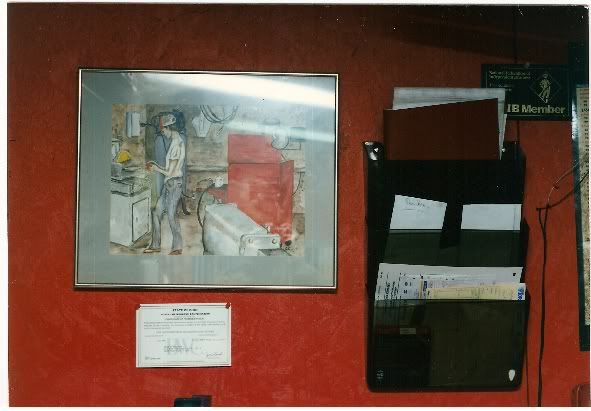

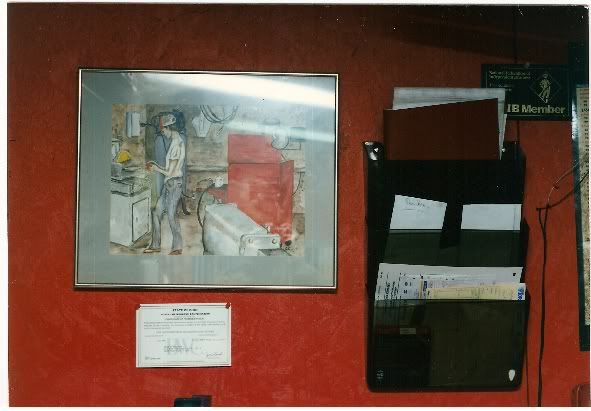

My mom can be quite the artist - and she painted this pic back when and labeled it "Small Beginnings". Assuming there was going to be bigger days ahead?

----------------

I am Ox and I approve this here post!

My shop did not start as a planned venture. I was actually employed by a [not so old] classmate and fellow dumb farmer in his stamping shop that he started while still finishing high skewl. I hired in a cpl yrs later and built die blocks and ran the grinders for the most part.

My first week on the job was 98 or 98-1/2 hrs and eventually got cought up enough that I werked my way down to 5-12's. I racked up prox 5000 hrs in a yr and a half. While I didn't expect to make a million overnight being a newbie in the game, my pay was not escalating hardly a'tall, and coupled with being [nearly] the only tool box in the shop with the lowest pay I got pretty upset one day when I had to stand 3 deep in line to git in my toy box behind one guy making half aggin more and the boss. At that point you hafta stand back and ask "What am I dooin?"

Eventually something put me over the edge and I ended up at the end of one day grabbing a forktruck and loading my toybox in the truck. I came into werk the next day with a mill wrench and a calculator. At the end of the day we came to an agreement I guess.....

It would seem that 1989 was NOT a boom yr, although we at that shop were always swamped - but you'll have that at eny business on the way up eh? I thought that I could find something somewhere quickly enough. .... Wasn't to be. A chumm that had heard that I was sleeping late called up and said that another fella had quit and they had an opening at the gas station as a pumper/wrench if I was interested. ... Well why not, it's better'n nut'n...

Aboot that same time a feller that I was building some benders and such for at the old shop had also heard that I was not there enymore. Him and the old boss had had some confrontations a while back and had split ways already. He was thinking on puting in a mill and such and maybe hiring me on if I was interested? ...Beats dealing with the public! (gas station) Well it seems that his wife put the cabosh to that! But he said that if I was interested in buying my own equipment - he had enough werk to git me started. Well for this dumb farmer - that's quite an invitation if ever I heard one!

I was shopping for equipment days and werking the gas station 2nd shift for a while. I doo remember one day for sure that I was a cpl hrs late to werk (I called in) as my day had been longer than hoped, but I had a $400 Kalamazoo saw in the back of the truck!

After a few weeks I was up and running and quit the gas station and was back at the long hours once again. I had been away from the shop for prolly less than 2 months, and I was surprised how quickly the trade had seemed to slip from me. I had to stop and think aboot things that had been routine just a cpl months ago. But soon it was all back and now I had to doo design as well as build. I was up for eny challange - I was 22, single, and had nothin' to lose!

After a few weeks I was up and running and quit the gas station and was back at the long hours once again. I had been away from the shop for prolly less than 2 months, and I was surprised how quickly the trade had seemed to slip from me. I had to stop and think aboot things that had been routine just a cpl months ago. But soon it was all back and now I had to doo design as well as build. I was up for eny challange - I was 22, single, and had nothin' to lose! I started with a mill, grinder, kick start phase convertor, and an air compressor. I had essentially no experience on a lathe and so I didn't rank that high on my needs list and decided that I could just farm out that for now. Within 6 months tho - I had decided that I could easilly make payments on a lathe with all the $ that I was farming out - and found a 16x36 LeBlond from the war.

I did not see the machine run, and found out when I got it hooked up that the main power shaft had been sheared off somehow. ??? OK, so now I got the machine apart and have two power shafts and all I really need is one. What's a feller to doo? I thought that they looked like they could simply be faced true and actually be bolted back together. So what - take it to a shop with a "werking" lathe? I didn't have that kinda $. Keep in mind that I am a 22 yr old broke plowboy. I have been werking on my own in many regards for many yrs. I quickly came up with a plan! Chuck up the shafts in the lathe and sspin the chuck by hand and fix it... and that's exactly what I did!

I had the machine for maby 15 more years and I NEVER had another issue with that (or any others that I can think of) shaft!

I had the machine for maby 15 more years and I NEVER had another issue with that (or any others that I can think of) shaft! These pics are from "Stage 1" which could also be referred to as a 1-1/2 truck garage.

My mom can be quite the artist - and she painted this pic back when and labeled it "Small Beginnings". Assuming there was going to be bigger days ahead?

----------------

I am Ox and I approve this here post!

Drove it home easy. Drove to werk the naxt week - easy. Scrounged some clean used one owner rod & main bearings from some local chumms and robbed a good crank out of a doner 305 and fixed the motor for the cost of 5 qrts of oil, a filter, and by means of pcing together the wrong-handed dipstick gaskets left over from some previous project.

Drove it home easy. Drove to werk the naxt week - easy. Scrounged some clean used one owner rod & main bearings from some local chumms and robbed a good crank out of a doner 305 and fixed the motor for the cost of 5 qrts of oil, a filter, and by means of pcing together the wrong-handed dipstick gaskets left over from some previous project.

Had I known that it would be that bigg'a deal - I would have incorpporated that feature somehow. But I am sure the piggy bank would'a squeeled heavilly. LOL!

Had I known that it would be that bigg'a deal - I would have incorpporated that feature somehow. But I am sure the piggy bank would'a squeeled heavilly. LOL!

Still had to deal with that GOD awfull drag type chip conveyor tho. When I got off the dairy farm I thought that I was done dealing with broken shit spreader chains (only break when full eh?). I was wrong.

Still had to deal with that GOD awfull drag type chip conveyor tho. When I got off the dairy farm I thought that I was done dealing with broken shit spreader chains (only break when full eh?). I was wrong.