Hi there!

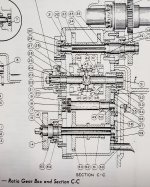

I recently picked up my first lathe, Pratt & Whitney Model C 16x30. I have found and read mostly everything I can about these lathes and I think I am now starting to re-read all the same stuff. It seems in pretty good shape, ways are great, spindle bearings are good, and just gave it a solid wipe down. Next is starting it up as I only got it on Saturday. I need to ensure the fluids are all good. Hoping this post revives some conversation on these lathes, I know they are getting more and more rare and hope to bounce some questions on some others that own or have owned one before.

I recently picked up my first lathe, Pratt & Whitney Model C 16x30. I have found and read mostly everything I can about these lathes and I think I am now starting to re-read all the same stuff. It seems in pretty good shape, ways are great, spindle bearings are good, and just gave it a solid wipe down. Next is starting it up as I only got it on Saturday. I need to ensure the fluids are all good. Hoping this post revives some conversation on these lathes, I know they are getting more and more rare and hope to bounce some questions on some others that own or have owned one before.