Hi All

Need some help from the group. I've disappeared for about 2+ years, I have been building a new shop...meaning dug the hole, poured concrete, framed, roofed, sided, wired, ducting, garage doors, homebrew security system, a bunch of stuff, closing in on the finish drywall...have all mental acuities and all 10 fingers and toes still

However I have a bad problem with my 10N. In waiting to finish up the new shop I've been powering up the control regularly and letting the phase perfect recharge the memory batteries. All good until around Oct Nov when I had a memory parity error. Next time I had a ? fault but most of the parameters were ***. Crap.

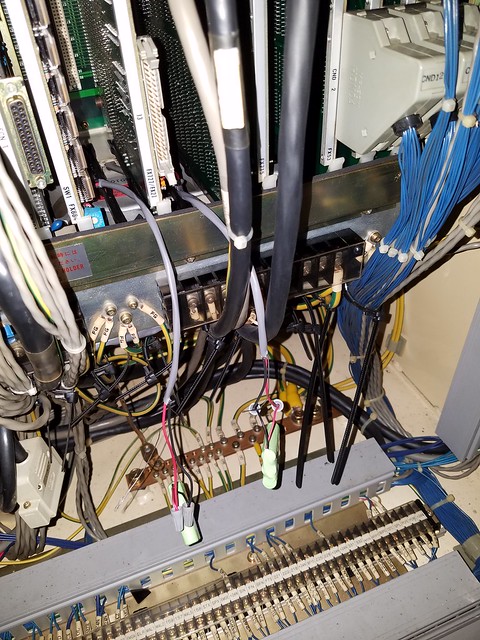

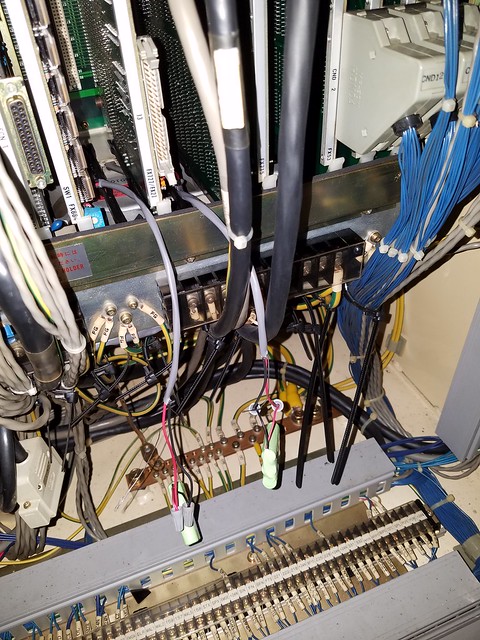

I solved the easy battery problem by getting some 600mAh NiMh batteries to wire to the circuit boards in place of the 200mAh triple cells which were like 4x the cost. Ok so they're just hanging by wire nuts but the functionality is there

I photographed all of the parameter screens in the past, thinking it would be useful, and now it hopefully will be...

I have an error for parameter M1-M12 invalid, so i tried re-entering those according to the list. Those all entered but some of the higher M parameters in the next column won't take the proper number via manual entry.

I read a memory reset & recovery procedure from Mazak dated '89. 89-002, and now I have a few questions.

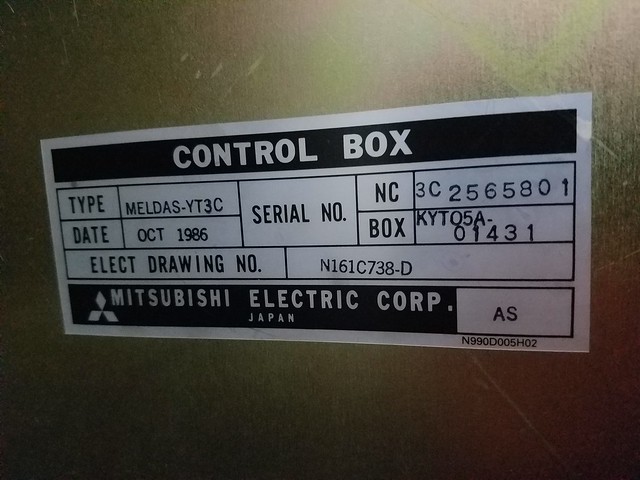

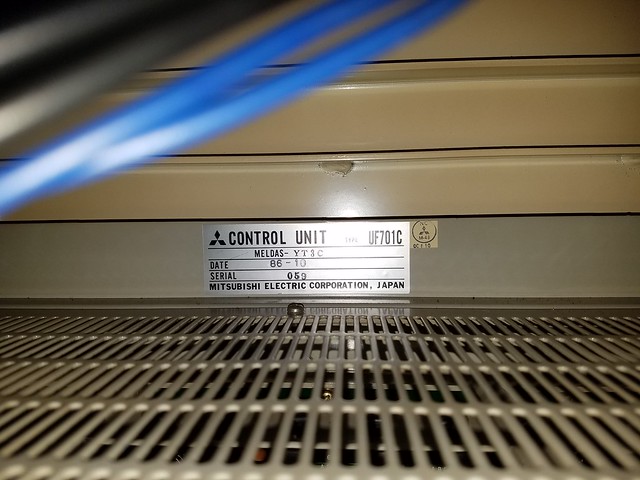

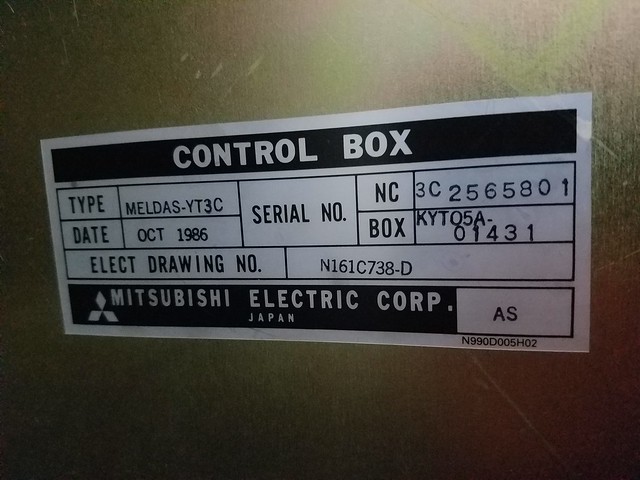

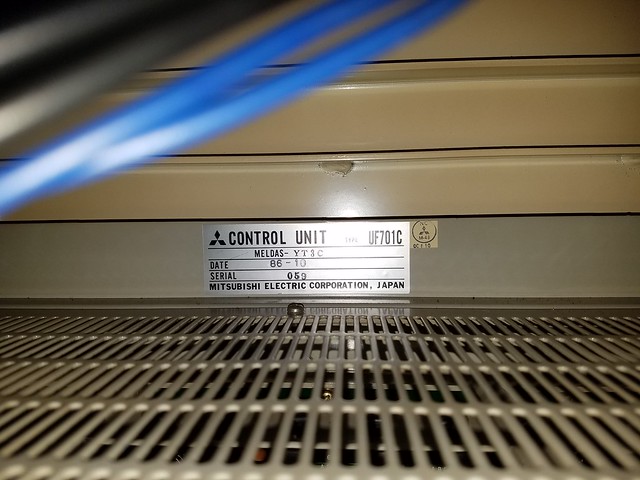

- It references the version of the control, B-C-D-E-F, based on the following pics I'm going to guess "C"

The procedure references needing a "microdisk" for versions C and higher, I've poked around some but no idea where this would even go into (is it like a CF or SD or ?) card or something I'd have to buy from Mazak? I got a pile of paper manuals with the machine but not anything like that.

Also the procedure references "secret parameters" by entering 1311 after touching the 3rd button from right on the Param page, but I can't get that...is it possible I don't have any "secrets" ?

The procedure references a full reset/hard-cold-start involving pulling cards and flipping dip switches, and purposefully discharging the memory capacitor to zero. I don't think I have much to lose because the programs and tools are all gone now.

Any advice appreciated here, sort of

and of course mad at myself that I let a few $ in batteries get the best of me...but I'm vowing to conquer this, learn some more, setup a better system, finsh the damn shop and get back to machining

Thank you!

Click to expand...

and of course mad at myself that I let a few $ in batteries get the best of me...but I'm vowing to conquer this, learn some more, setup a better system, finsh the damn shop and get back to machining

and of course mad at myself that I let a few $ in batteries get the best of me...but I'm vowing to conquer this, learn some more, setup a better system, finsh the damn shop and get back to machining