eKretz

Diamond; Mod Squad

- Joined

- Mar 27, 2005

- Location

- Northwest Indiana, USA

CBN for me. Hands down.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

QT: (You could give it a shot,) I would not take a chance on a customer's part or buy an expensive wheel not knowing/thinking it might work....with not making a few tests.

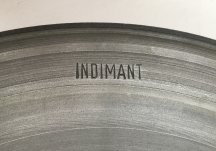

Pretty sure that the obscured letters say:Glad it worked out for you. Figured it would probably be fine. 1A1 is the wheel type, B is for Borazon, just means CBN. 126 is average grit size in microns. The last bit is probably concentration of grit and perhaps bond info. 187551 is a part number. Indimant is probably the brand name. Can't help with the exact concentration and bond info. I can't imagine that it's 18% concentration.

I'm curious, if I use it on unhardened steel, what will happen? Will it clog quickly?

Buck, you were partly responsible for my trying this in the first place, because a long time ago you wrote something like "a good grinder can make do with almost any grinding wheel, it just might not be as effective or efficient", or something like that. So even though most people said, "you should use diamond for glass" I tried the CNB anyway.Creep-feed-plunge would have been ok..but you did a fine job of it.

Did it make any noise when grinding?

Nice set-up.

*Now you have a new hat. Lens grinding 50 bucks an hour.

Oh..did you mention part RPM ? (the rest of the story)

( if I use it on unhardened steel,) likely to get noisy crying for a dress, drag-down RPM, and start eating up dollars.

Thank you.I think your setup and process were excellent...and a part well done.

Holding the lens was not a problem. I held the lens on the concave side. The aluminium mushroom was slightly convex, to more-or-less fit that. Then a piece of double-sticky tape. The mushroom was 35mm in diameter, and the tape was about 38mm in diameter. Final ground size was 36.9, and the tape protected the surface very well on that side.Thinking about other possible methods, I thought that two thin balsam wood washers made to the diameter of the lens would keep grits off the lens face, compress so as to exert even pressure, and allow indicating adjustment to the original OD. They could be OD ground in place when grinding the lens OD, and be Elmer's glue stuck to two face plates

That was also my impression: the friable glass is lightly but constantly dressing the wheel.Yes, work loading the wheel is a possibility...but I think grinding glass unclogs a wheel.

Yes, I think balsam might have worked. Not sure I want to put PVA glue (Elmers) onto a coated lens.(Note: I have used Elmer,s glue for one ups and it holds fine and makes an easy cleanup with being water soluble...the surface tension of the balsam would hold well)..I would make a simple hole punch for the balsam washer ID and cut the OD with scissors to +1 or 2 MM.

I first put the aluminium mushroom in a collet, but the lens was not running close enough to center. So then I stuck it into my ancient Grip-Tru chuck and centered it to 5 microns. Then I ground.One advantage might be that with not using the double-back, adjusting OD run out might be easier..Faceplates might be made with a small concave hollow to ensure an intersection near the lens OD..

Notice

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.