The spindle bearings on one of my lathes need replacing. We've done this on other lathes in-house before. I didn't want to mess with it this time, though, so I got a quote from a spindle rebuilder. I was surprised by the (high) price. It's an old Takisawa TC-1. The max bar size is only about 1", so it's a pretty small spindle. The rebuilder quoted me around $4k. I don't see how they charge this much. I would still have to pull the spindle and ship it to them. I figure bearings are only around $600. So, what's so magical about changing bearings in a lathe spindle? Like I said, we've done it before, and those machines are all still running fine. The rebuilders website says that they balance the spindle, but I don't really see the need. Am I missing something when it comes to spindle bearing replacement?

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Replacing lathe spindle bearings

- Thread starter wmpy

- Start date

- Replies 18

- Views 3,037

Panza

Stainless

- Joined

- Oct 23, 2005

- Location

- Lillehammer, Norway

I have wondered about the same thing. I heard a price of more than $7K for just the bearing replacement like you say.

Milland

Diamond

- Joined

- Jul 6, 2006

- Location

- Hillsboro, New Hampshire

Among other things, they're hopefully using (fairly large) "name brand" spindle bearings, rather than cheaper products. They're also carrying a warranty burden that must be accounted for, especially since they're not reinstalling the spindle and have to deal with the occasional "customer caused damage, but says it's our fault" situation.

$4K for cleaning, disassembly, new bearing installation and balance doesn't sound too bad to me if the warranty is decent and it gets done reasonably fast.

$4K for cleaning, disassembly, new bearing installation and balance doesn't sound too bad to me if the warranty is decent and it gets done reasonably fast.

Conrad Hoffman

Diamond

- Joined

- May 10, 2009

- Location

- Canandaigua, NY, USA

Hopefully they're also doing a lot of measurement and checking that most people aren't set up to do.

BT Fabrication

Titanium

- Joined

- Nov 3, 2019

- Location

- Ontario Canada

The spindle bearings on one of my lathes need replacing. We've done this on other lathes in-house before. I didn't want to mess with it this time, though, so I got a quote from a spindle rebuilder. I was surprised by the (high) price. It's an old Takisawa TC-1. The max bar size is only about 1", so it's a pretty small spindle. The rebuilder quoted me around $4k. I don't see how they charge this much. I would still have to pull the spindle and ship it to them. I figure bearings are only around $600. So, what's so magical about changing bearings in a lathe spindle? Like I said, we've done it before, and those machines are all still running fine. The rebuilders website says that they balance the spindle, but I don't really see the need. Am I missing something when it comes to spindle bearing replacement?

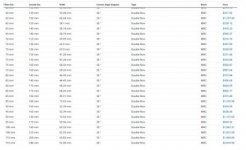

bearings can be 400-800 each and some have stacked bearings so it takes 2 on each end of it. plus all the seals etc. some like a 100MM ID bearing which would make a 70mm or less spindle is $1062 each. cant seem to size this screen shot up though, sorry guys

Attachments

Milland

Diamond

- Joined

- Jul 6, 2006

- Location

- Hillsboro, New Hampshire

Hopefully they're also doing a lot of measurement and checking that most people aren't set up to do.

Yeah, that should be part of the rebuild cost. It may also include a kiss grind on the chuck mount surfaces.

Hopefully they're also doing a lot of measurement and checking that most people aren't set up to do.

Can you explain further what kind of measurement might be done? I'm assuming that they would check for face and radial run-out, but can't I do that? What else is there other than that and balancing?

I got a similar response from the machine tool builder...

"Customer most likely will not be able to perform the correct tests to assure that the spindle is running at the original accuracy."

kustomizingkid

Titanium

- Joined

- Aug 2, 2010

- Location

- Minnesota

Do it yourself then.

bearings can be 400-800 each and some have stacked bearings so it takes 2 on each end of it. plus all the seals etc. some like a 100MM ID bearing which would make a 70mm or less spindle is $1062 each. cant seem to size this screen shot up though, sorry guys

View attachment 338627

According to the specs and drawings in the book, there are two pairs of angular contact ball bearings at each end of the spindle. Bearing ID is 80 mm.

Milland

Diamond

- Joined

- Jul 6, 2006

- Location

- Hillsboro, New Hampshire

Damn I just changed my spindle bearings on my lathe and it cost me around 50 bucks and I have around .001 runout. Found some SKF bearings on Ebay. I wonder how much of this CNC repair world is just an overpriced facade.

Umm - .001" is crap for lathe spindle runout. We're talking a proper machine tool here, not a toy. And the other issues (proper preload, axial play, temp rise while running, etc.) are unknowns.

[Don't intend to offend, but it is what it is]

Vancbiker

Diamond

- Joined

- Jan 5, 2014

- Location

- Vancouver, WA. USA

....... it cost me around 50 bucks and I have around .001 runout. .....

You do know that's at least 5X more than a good lathe should have????

Milland

Diamond

- Joined

- Jul 6, 2006

- Location

- Hillsboro, New Hampshire

you do know that's about 5x more than a good lathe should have????

10x.......

The spindle bearings on one of my lathes need replacing. We've done this on other lathes in-house before. I didn't want to mess with it this time, though, so I got a quote from a spindle rebuilder. I was surprised by the (high) price. It's an old Takisawa TC-1. The max bar size is only about 1", so it's a pretty small spindle. The rebuilder quoted me around $4k. I don't see how they charge this much. I would still have to pull the spindle and ship it to them. I figure bearings are only around $600. So, what's so magical about changing bearings in a lathe spindle? Like I said, we've done it before, and those machines are all still running fine. The rebuilders website says that they balance the spindle, but I don't really see the need. Am I missing something when it comes to spindle bearing replacement?

A good spindle shop would remove the old bearings, check the condition of the spindle itself, hard chrome plate, precision grind, then plate again the spindle, re-assemble the spindle with new bearings and preload to spec, run in the spindle and check the temprature, vibration, and balance of the spindle as well as the runout and taper at different locations.

There is a lot that goes into getting a spindle factory spec or better and that involves a lot of testing and correction that most guys don’t want to bother with.

In my experience I’ve never regretted getting a dedicated shop to fix my stuff, it always comes out amazing and fast, you just gotta pay for it.

Conrad Hoffman

Diamond

- Joined

- May 10, 2009

- Location

- Canandaigua, NY, USA

I'd guess any decent rebuild shop would have air bearing roundness measurement equipment, plus the ability to measure just about anything down to 10 millionths or so. Weren't some Hardinge spindles spec'd at 25 millionths runout? They're be able to kiss grind bearing seats and probably touch up tapers. They'll stock a dozen specialty and expensive lubricants and know where to use them. That said, I still do all my own bearings for my home shop because my machines don't make me enough money to buy tooling, much less bearings.

Orange Vise

Titanium

- Joined

- Feb 10, 2012

- Location

- California

$4K seems reasonable for a lathe spindle. Live toolholder rebuilds can cost $2K and up depending on the type.

They're not making hand over fist. If spindle rebuilding were cheap, easy, and highly profitable, companies would be sprouting up all over the place, each one undercutting the previous one. But that doesn't happen, and it's not just a matter of time because rebuilders have been around for decades.

They're not making hand over fist. If spindle rebuilding were cheap, easy, and highly profitable, companies would be sprouting up all over the place, each one undercutting the previous one. But that doesn't happen, and it's not just a matter of time because rebuilders have been around for decades.

Fadriver

Aluminum

- Joined

- Apr 24, 2011

- Location

- los angels ca.

$4K seems reasonable for a lathe spindle. Live toolholder rebuilds can cost $2K and up depending on the type.

They're not making hand over fist. If spindle rebuilding were cheap, easy, and highly profitable, companies would be sprouting up all over the place, each one undercutting the previous one. But that doesn't happen, and it's not just a matter of time because rebuilders have been around for decades.

Well you are wrong they make heck of money quick, reason there are few people in that trade

I take ballscrew to my guy and charges cash no check $900 does the work like in an hour he says

in few hours about an hour later calls say is ready, some are scammers they say need to re-grind

and re-chrome and want insane money , same for spindle bearings , some time is only pre-load and charge

insane i know where owner house is an rea where only rich can afford. It comes to skills , they learned a trade , most worked for big spindle bearing companies so they know what bearing fits where to buy etc.

I worked and a company like year 95, company paid invoices like $ 7500 to reputable anahein ca. based company and i betch you ,probably was only the pre-load after a crash, but back then companies were minting money they only care how soon spindles would be running, I only can speak for myself and know

how difficult its to see money doing machining and see shop next door charges 20k for a metal gate

anyway they deserve their money some people are lucky others not so.

Fadriver

Aluminum

- Joined

- Apr 24, 2011

- Location

- los angels ca.

The spindle bearings on one of my lathes need replacing. We've done this on other lathes in-house before. I didn't want to mess with it this time, though, so I got a quote from a spindle rebuilder. I was surprised by the (high) price. It's an old Takisawa TC-1. The max bar size is only about 1", so it's a pretty small spindle. The rebuilder quoted me around $4k. I don't see how they charge this much. I would still have to pull the spindle and ship it to them. I figure bearings are only around $600. So, what's so magical about changing bearings in a lathe spindle? Like I said, we've done it before, and those machines are all still running fine. The rebuilders website says that they balance the spindle, but I don't really see the need. Am I missing something when it comes to spindle bearing replacement?

If your are machining shop and are minting money pay for, if struggling to make ends meet do it, I always struggling to pay my bills, so i google for cheaper prices , and found a guy thru the internet add, and end up in a residential nice neighborhood working out a one car garage, equipment less than 5k, secret is clean everything nice from start to finish, need a 50 ton hyd press, a steel pipe and maybe dry ice for the shaft, a 110 v lamp and 12 hr. time to expand and press it straight no hammer allowed, another point front collar put drain hole facing conveyor, do not rush or mark before removal, they give you a pep talk that is like building a neuks , reason they smart, they know a lathe makes money, a car not you can ride or bus, removing and putting back from lathe is more work involved .

Similar threads

- Replies

- 9

- Views

- 410

- Replies

- 48

- Views

- 2K

- Replies

- 42

- Views

- 3K

- Replies

- 18

- Views

- 2K