Thornewmexico

Aluminum

- Joined

- Aug 11, 2011

- Location

- SW, USA

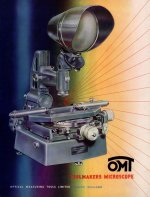

I have wanted a toolmaker microscope for a while. Mitutoyo toolmaker microscopes always went for too much to interest me at auction. Specialty Screw Machine Products in Lancaster, PA was auctioning off their toolmaker scopes, and the first one went for a relatively low amount of money. I bid on this one which looked pretty complete, and was successful for a bid of only $100. The shipping agent charged me about $250 for shipping because it was much heavier (85 pounds) than I would have ever guessed from a web picture, and it was somewhat larger than I would have thought at 13" x 17" x 19". The resulting box and padding was quite large. The scope was packed with foam padding about 2" thick on all sides and arrived undamaged. This is what it looked like in the auction pic:

Survey of the scope showed that there was the expected XY movement table, with a means for limited rotation around the Z and X Axis. Including the focus mechanism (Z axis), I count five degrees of freedom of movement. As far as function, the X axis moved okay, but the Y axis was virtually frozen in place. It was very dirty and sticky, apparently covered with dried coolant residue and lubricating oil. It also had none of the three lights it should have had.

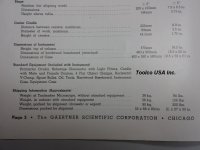

This is what I have learned to this point:

Gaertner Scientific Corporation has been around for a long time. They are still there in the Chicago area, but have changed ownership over the years. Their current model of toolmaker scope was about $19K, with all sorts of bells and whistles included at no extra charge. I called them, and was somewhat disappointed when I was told that the scope I purchased was no longer supported by Gaertner in anyway. There was no information available regarding this scope, not even a manual. All the people who knew about this scope were dead. Then the person I was speaking to abruptly hung up. Well! I might as well have bought something from China. I decided to continue my quest despite the shocking degree of rudeness I had just been subjected to.

At first I thought the scope while at the factroy was merely placed near a place where coolant was used. However, when I started disassembly, I found just as much dried coolant inside the scope as on the outside. In addition, while not covered in chips, it had a had a small amount of chips, some inside. Also, there were tiny parts found inside. Some of these parts had diameters of 0.025". The auction also sold a bunch of tiny watchmaker lathes. I suspect this scope was used to visualize parts during the machining process, which would account for the chips, parts and coolant residue. A representative picture of the base after disassembly showing dried coolant inside the scope base:

As I was disassembling the scope, I realized this is a very complicated device. There were eight large iron castings with at least two smaller ones made of bronze. The XY axes move on individual cylindrical roller bearings. The XY movement action when freed up from the dirty /stuck micrometer screws and cables was very smooth with almost no effort required to move it. There is a cable system which can be adjusted to permit automatic return to a starting XY position. There is an option of measurement with gage blocks on the X axis. I didn't find a means of measuring angles yet. I might be missing a reticle, or perhaps the scope was too dirty to see it. I'll know more when I get this thing reassembled. This scope has +/- 300 parts. Construction techniques include casting, pressing, stamping, peening, soldering, and machining (EDIT: also grinding, heat treating and scraping). I originally heard this description applied to the Hardinge HLVH lathe, but I think it applies to this scope also: It was made to a specification, not a price point. I have not seen everything by any means, but I would say this is one of the most complicated measurement machines I have ever seen, certainly the most complicated one I ever took apart.

These are pictures of the cleaned parts.

Cleaned up iron castings, some partially assembled:

Smaller Parts, some partially assembled:

The fasteners, bearings, and other small parts. Red lid has parts found loose in the scope.

I am hoping I took enough pictures during disassembly to reassemble this thing. Just to be safe, I was at an estate sale (described recently in a different thread) where there was a similar Gaertner scope for sale at a bargain price, so I bought that one also. It should help with reassembly. Since both of these are missing a few parts, I might use it as a donor for this one.

Survey of the scope showed that there was the expected XY movement table, with a means for limited rotation around the Z and X Axis. Including the focus mechanism (Z axis), I count five degrees of freedom of movement. As far as function, the X axis moved okay, but the Y axis was virtually frozen in place. It was very dirty and sticky, apparently covered with dried coolant residue and lubricating oil. It also had none of the three lights it should have had.

This is what I have learned to this point:

Gaertner Scientific Corporation has been around for a long time. They are still there in the Chicago area, but have changed ownership over the years. Their current model of toolmaker scope was about $19K, with all sorts of bells and whistles included at no extra charge. I called them, and was somewhat disappointed when I was told that the scope I purchased was no longer supported by Gaertner in anyway. There was no information available regarding this scope, not even a manual. All the people who knew about this scope were dead. Then the person I was speaking to abruptly hung up. Well! I might as well have bought something from China. I decided to continue my quest despite the shocking degree of rudeness I had just been subjected to.

At first I thought the scope while at the factroy was merely placed near a place where coolant was used. However, when I started disassembly, I found just as much dried coolant inside the scope as on the outside. In addition, while not covered in chips, it had a had a small amount of chips, some inside. Also, there were tiny parts found inside. Some of these parts had diameters of 0.025". The auction also sold a bunch of tiny watchmaker lathes. I suspect this scope was used to visualize parts during the machining process, which would account for the chips, parts and coolant residue. A representative picture of the base after disassembly showing dried coolant inside the scope base:

As I was disassembling the scope, I realized this is a very complicated device. There were eight large iron castings with at least two smaller ones made of bronze. The XY axes move on individual cylindrical roller bearings. The XY movement action when freed up from the dirty /stuck micrometer screws and cables was very smooth with almost no effort required to move it. There is a cable system which can be adjusted to permit automatic return to a starting XY position. There is an option of measurement with gage blocks on the X axis. I didn't find a means of measuring angles yet. I might be missing a reticle, or perhaps the scope was too dirty to see it. I'll know more when I get this thing reassembled. This scope has +/- 300 parts. Construction techniques include casting, pressing, stamping, peening, soldering, and machining (EDIT: also grinding, heat treating and scraping). I originally heard this description applied to the Hardinge HLVH lathe, but I think it applies to this scope also: It was made to a specification, not a price point. I have not seen everything by any means, but I would say this is one of the most complicated measurement machines I have ever seen, certainly the most complicated one I ever took apart.

These are pictures of the cleaned parts.

Cleaned up iron castings, some partially assembled:

Smaller Parts, some partially assembled:

The fasteners, bearings, and other small parts. Red lid has parts found loose in the scope.

I am hoping I took enough pictures during disassembly to reassemble this thing. Just to be safe, I was at an estate sale (described recently in a different thread) where there was a similar Gaertner scope for sale at a bargain price, so I bought that one also. It should help with reassembly. Since both of these are missing a few parts, I might use it as a donor for this one.

Last edited: