300sniper

Hot Rolled

- Joined

- Nov 14, 2006

- Location

- Greenwood, Ca

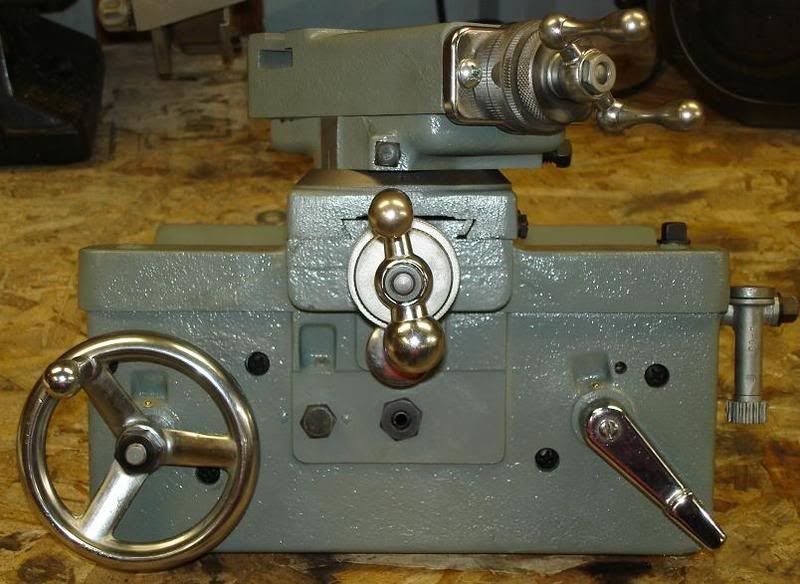

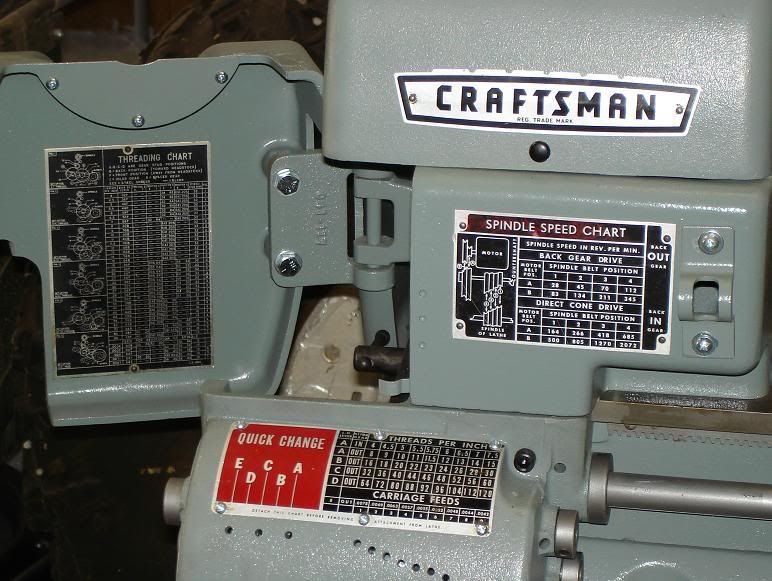

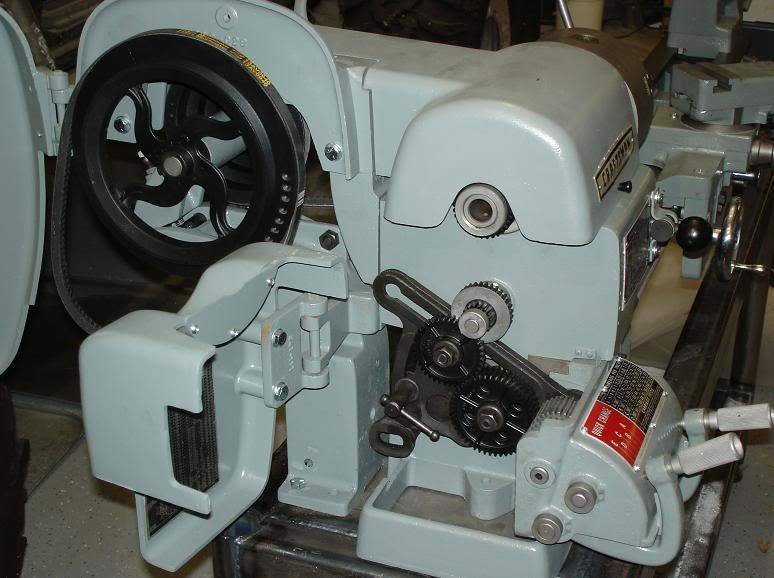

i was just going through some of my pictures and thought you may like to see the restoration of my old craftsman 101.27590 12x36 lathe. i put a ton of time into restoring it but ended up getting a new, larger lathe and just didn't have the room for the craftsman anymore. as much as it hurt to do, i had to sell it. i did make out ok selling it though as i got what i was asking.

when i got the lathe it was in good mechanical shape and still very tight. it was in rough shape cosmetically from sitting in someone's barn for years.

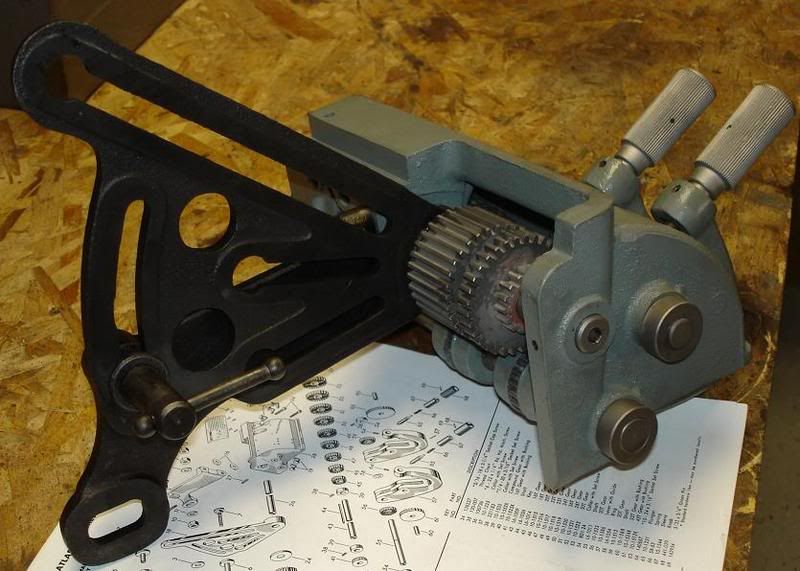

this is the lathe when and where i bought it.

when i got the lathe it was in good mechanical shape and still very tight. it was in rough shape cosmetically from sitting in someone's barn for years.

this is the lathe when and where i bought it.