Gents, thanks for giving this one some thought.

Cal - I appreciate the detailed process suggestions.

As everyone can imagine - I've been having my own internal dialog on options/trade-offs/order of operations.

First - the head stock:

I have some experience with Evapo-rust - it can be exceptionally useful, but there are some things to watch out for.

As noted - it's water based.

Also, the dreaded "etch" line that occurs if things are partially submerged.

That's pertinent here - because at lease one of the most affected gears is EE1121 and EE1151 (I believe) is on the spindle shaft itself.

That said, my experience with Evapo-rust is minimal flash rust, and coating/bathing in WD40 or oil after rinse gives the parts good shelf life before assembly.

Seems like we are all on that page - but the question is what would be best process.

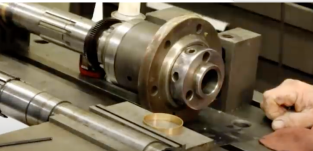

Below is my headstock (distant shot to orient - close up to see gear condition)

Close up

The rust affected components can be seen.

To attack these, Ive been considering filling the machine to a level that just submerges the cog depth, but sits below the bearing height, and having the machine rotate very slowly to bathe these parts.

(how I would rotate it - at this juncture - is a different topic...)

I've wondered if the Evapo-rust would run past EE-1124 (the copper colored spindle "race" (not sure its name), and into the front reservoir?

I also considered filling it lower, and using a fish pump and circulating the Evapo-rust - and "bathing" the affected gears with the recirculation hose.

Not sure if this will or won't have the desired affect.

Cal - sounds like you've had some less than successful experiences with it.

I've seen it done with success but on longer cycles with under body of automobiles.

However - some liquid would probably find its way into the bearings...

I understand everyone's reticence with putting water anywhere near the bearings.

With that said, its possible those bearing already have rust on them - and would benefit from a thorough bathing in Evapo-rust while slowly tumbling.

A lemonade from lemons opportunity.

My experience with bearings in Evaporust is quite good.

That said - even if my intention were to go ahead and submerge the bearings, then rinse and coat them (as per Cal), I'm not sure I

could do it.

Reason: If the level in the main reservoir was filled to the top for example, wouldn't that liquid just run out the front and rear bearings and leak out of the machine where the spindle exits at the nose and rear?

I don't believe there are any rubber seals on any of the shafts as they pass through either the bearings or the headstock itself?

One possibility would be this bath method, followed by something like Cals rinse and coat method - but filling the kerosene all the way to the top of the reservoir - letting it spill/rinse out any areas that the evap-orust may have found its way to - then following that with the same treatment using oil.

Welcome feedback even if it's just to throw tomatoes...

Gear Box

Here - the gears and shafts look quite good to me overall.

There is some corrosion - but it seams to be at the castings - rather than the internal components.

I assume the same issue exists - if I were to try and completely fill this - the Evapo-rust would likely just flow out the bearings where the shafts penetrate the gear box castings?

Unless I plan to remove the gear box in total - I might not be able to attack the corrosion that is mostly high up.

So perhaps it's either remove and service

or flush with kerosene, add fresh oil, and move on.

I am considering.

Stills from my video below showing gear box current condition.

Again - welcome critiques/counter points to what I am seeing.

(Video link here for convenience)