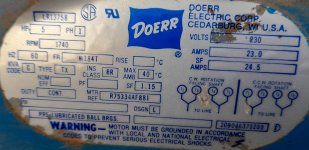

looking for a run capacitor to the 5 HP Doerr motor powering the families air compressor... no-one knows or has documentation as to what is supposed to be... and the cap in it is rusted beyond legibility. compressor is Emglo model Y5B-80V serial 102588029 powered by a Doerr 5HP Motor 5 hp probably made 1988 as that is when the pressure tank was made. the UL and CSA file on it is LR13758 label reads: 5HP 1 Phase 1740 Rpm m184t frame Mtr ref: r75334af881 thinking this is like a model number... 60Hetz, 230 volts, 23.0 amps, SF amps 24.5, SF 1.15 insulation class BR type TX KVA code G and then a final long number in the bottom right that is not labeled is 20(B or 8)046370200 ....it says everything but does not tell me the capacitor sizes. would appreciate a call if someone can educate me on this.. wife is pissed the compressor is still preventing me from finishing cleaning the garage... I am at the point where I want to simply measure current draw and try to dial in a size iteratively. however, I am not sure what my target characteristic setup should be and I am hoping you would advise 773-2258558 is my cell Mark...I used formulas from websites and calculated 98uF if its 84 percent efficient and 91uF if its 78 percent efficient but the efficiency is not specified and I dont know how to extract it from the data available... more importantly another website says a 5hp run cap is never over 40uF so I am begging for help.. will venmo or quickpay BEER MONEY! already replaced bearing and cleaned and painted this compressor up..

snippits from emails I sent to allot of people that may be applicable but basically someone has this motor and if they could remove the cover and tell me what the cap is supposed to be I WOULD LOVE YOU FOR IT

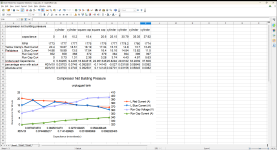

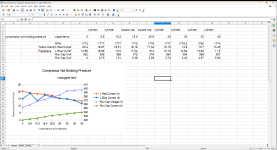

since the efficiency is not specified on the label I am uncomfortable doing the calculation with a 75percent approximation which also gives me an uncomfortable 88.14uF Capacitor and it goes up from there...98.71uF for 84 percent efficiency using this formula....

The single-phase capacitance C(µF) in microfarad is equal to 1000 times the product of power P(W) in watts and efficiency η divided by the product of voltage V(V) in volts square and the frequency F(Hz). The formula for calculating capacitor value is

C(µF) = (P(W) x η x 1000) / (V(V) x V(V) x f)

found on this website calculator:

Single phase Motor Capacitor Calculation calculator | Electrical4u

Maybe this was supposed to be a starting capacitance? but what's in there now is much bigger. This has been occupying my mind for months

and months', searching for a solution...wife is going nuts so i have to finish this compressor off to finish the garage clean up... thinking of trying a 30 uF and then increasing receiving current draw by trial and error on the two legs of the single phase electrical connection and searching for the capacitance value resulting in smallest current but I am just guessing at this point ... what I am thinking is the motor actually spun over in the winter with the blown capacitor so as long as I do not exceed the capacitance I believe I won't damage the motor, I really would appreciate learning a good method of getting to a value as this is not the first time in my life this would have been useful and I'm pretty sure it won't be the last..... I am in a dangerous state, I don't know what I don't know.

snippits from emails I sent to allot of people that may be applicable but basically someone has this motor and if they could remove the cover and tell me what the cap is supposed to be I WOULD LOVE YOU FOR IT

since the efficiency is not specified on the label I am uncomfortable doing the calculation with a 75percent approximation which also gives me an uncomfortable 88.14uF Capacitor and it goes up from there...98.71uF for 84 percent efficiency using this formula....

The single-phase capacitance C(µF) in microfarad is equal to 1000 times the product of power P(W) in watts and efficiency η divided by the product of voltage V(V) in volts square and the frequency F(Hz). The formula for calculating capacitor value is

C(µF) = (P(W) x η x 1000) / (V(V) x V(V) x f)

found on this website calculator:

Single phase Motor Capacitor Calculation calculator | Electrical4u

Maybe this was supposed to be a starting capacitance? but what's in there now is much bigger. This has been occupying my mind for months

and months', searching for a solution...wife is going nuts so i have to finish this compressor off to finish the garage clean up... thinking of trying a 30 uF and then increasing receiving current draw by trial and error on the two legs of the single phase electrical connection and searching for the capacitance value resulting in smallest current but I am just guessing at this point ... what I am thinking is the motor actually spun over in the winter with the blown capacitor so as long as I do not exceed the capacitance I believe I won't damage the motor, I really would appreciate learning a good method of getting to a value as this is not the first time in my life this would have been useful and I'm pretty sure it won't be the last..... I am in a dangerous state, I don't know what I don't know.

. My compressor's motor is 3450 RPM though, not sure if that makes any difference.

. My compressor's motor is 3450 RPM though, not sure if that makes any difference.