So whenever i get to make a part with an npt thread on or in it me and my coworker have always struggled. We have some working programs for the cnc lathe with offset notes and whatnot.

We have the gauges for the internal and external threads we need to make. But instead of struggling everytime another npt nightmare arrives i want to figure out where im messing up. Because it cant be that hard right?

So tomorrow i need to make a 3/4 inch internal npt thread in a part.

I plan on doing it this way.

From kennametal there is a thread calculator where i will pick 3/4npt and it will spit out the major and minor diameters at both ends of the thread

To make internal threads i have to make a bore up to the minor diameter.

I will start off with an 20mm(0.7874 inch) insert drill and profile the bore.

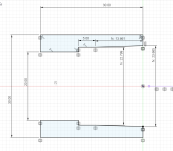

My bore will start at the minor large diameter(23.665 mm/0.9316 inch) and taper down to the minor small diameter(22.799 mm/0.8975 inch) over a length of 13.861mm/0.5457 inch with a few mm of straight bore to give my threading tool a litle room to taper out and give me a straight surface to measure the bore.

N1T101(ROUGH)

G0G40X19.Y0.G96S80M3

G0Z2.M8

G71U1.R0.2

G71P300Q400U-0.2W0.02F0.22

N300G0G41X25.

G1Z0.

G1X23.665

G1X22.799Z-13.861

G1Z-18.861

N400G1X19.

G0G40Z50.

G0G53X-50Y0.Z-350.M1

N2T202(FINISH)

G0G40X19.Y0.G96S120M3

G0Z2.M8

G70P300Q400F0.12

G0G40Z50.

G0G53X-50Y0.Z-350.M1

Profile in inch mode

N300G0G41X0.9842

G1Z0.

G1X0.9316

G1X0.8975Z-0.5457

G1Z-0.7425

N400G1X0.7480

After that i will draw up the thread with a 5mm(0.1968inch) lead in and a 2mm(0.0787inch) lead out to calculate my start and end point.

I start with the major large diameter(26.510mm/1.0437 inch) and the major small diameter(25.644mm/1.0096Inch) the length and extend that line in the z positive for 5mm(0.1968inch) to synchronize the spindle and in the z negative direction by 2mm(0.0787inch) to make sure my toolpath is long enough.

We always use a two line g76 when threading so the will look something like this

N3T303(NPT 14X60 )

G0G40X19.Y0.G97S800M3

G0Z5.M8

G76 P020060 Q60 R30

G76 Z-15.861 X25.52 R-0.62 F1.814

G0G40Z50.

G0G53X-50Y0.Z-350.M1

converted to inches

g0z0.1968

G76 P020060 Q60 R30

G76 Z-0.6244 X1.0047 R-0.0244 F0.0714

Last time i did it like this i had to adjust the bore dimension and the thread up in x by about 0.8-1mm to get it to gauge right so obviously i am doing something wrong.

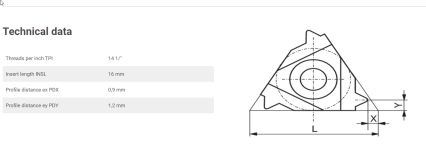

I did figure out i didnt account for the tip of the threading insert

so i offset the threading path by 1.2mm(0.0472inch) that helped a litle but i still had to offset quite a bit.

Can anyone of you help me figure out what im doing wrong because im feeling pretty stupid by now.

Thank you

We have the gauges for the internal and external threads we need to make. But instead of struggling everytime another npt nightmare arrives i want to figure out where im messing up. Because it cant be that hard right?

So tomorrow i need to make a 3/4 inch internal npt thread in a part.

I plan on doing it this way.

From kennametal there is a thread calculator where i will pick 3/4npt and it will spit out the major and minor diameters at both ends of the thread

To make internal threads i have to make a bore up to the minor diameter.

I will start off with an 20mm(0.7874 inch) insert drill and profile the bore.

My bore will start at the minor large diameter(23.665 mm/0.9316 inch) and taper down to the minor small diameter(22.799 mm/0.8975 inch) over a length of 13.861mm/0.5457 inch with a few mm of straight bore to give my threading tool a litle room to taper out and give me a straight surface to measure the bore.

N1T101(ROUGH)

G0G40X19.Y0.G96S80M3

G0Z2.M8

G71U1.R0.2

G71P300Q400U-0.2W0.02F0.22

N300G0G41X25.

G1Z0.

G1X23.665

G1X22.799Z-13.861

G1Z-18.861

N400G1X19.

G0G40Z50.

G0G53X-50Y0.Z-350.M1

N2T202(FINISH)

G0G40X19.Y0.G96S120M3

G0Z2.M8

G70P300Q400F0.12

G0G40Z50.

G0G53X-50Y0.Z-350.M1

Profile in inch mode

N300G0G41X0.9842

G1Z0.

G1X0.9316

G1X0.8975Z-0.5457

G1Z-0.7425

N400G1X0.7480

After that i will draw up the thread with a 5mm(0.1968inch) lead in and a 2mm(0.0787inch) lead out to calculate my start and end point.

I start with the major large diameter(26.510mm/1.0437 inch) and the major small diameter(25.644mm/1.0096Inch) the length and extend that line in the z positive for 5mm(0.1968inch) to synchronize the spindle and in the z negative direction by 2mm(0.0787inch) to make sure my toolpath is long enough.

We always use a two line g76 when threading so the will look something like this

N3T303(NPT 14X60 )

G0G40X19.Y0.G97S800M3

G0Z5.M8

G76 P020060 Q60 R30

G76 Z-15.861 X25.52 R-0.62 F1.814

G0G40Z50.

G0G53X-50Y0.Z-350.M1

converted to inches

g0z0.1968

G76 P020060 Q60 R30

G76 Z-0.6244 X1.0047 R-0.0244 F0.0714

Last time i did it like this i had to adjust the bore dimension and the thread up in x by about 0.8-1mm to get it to gauge right so obviously i am doing something wrong.

I did figure out i didnt account for the tip of the threading insert

so i offset the threading path by 1.2mm(0.0472inch) that helped a litle but i still had to offset quite a bit.

Can anyone of you help me figure out what im doing wrong because im feeling pretty stupid by now.

Thank you

Attachments

Last edited: