IrbyJones

Stainless

- Joined

- Jun 9, 2005

- Location

- Poquoson, Va

Guys,

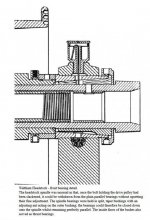

Long time ago there was a discussion about oilers like this one with a standpipe in the center. Folks were saying that a wick went from the oil reservoir up and over into the standpipe to draw oil down into the bearing, and sort of meter it also. In fact, Jim himself posted a picture of an example shown below. I wonder if the oiler for the Stark #4 should really have such a wick in it? I guess the far end would run all the way down and touch the spindle. A question for some more Stark #4 guys...

When Jim says "A better photo of how a wick-fed oiler is constructed:", this is the picture he is talking about:

The thread was here:

Antique brass oiler question

But some of the pictures are no longer available because the Metalworking Dropbox where they resided has changed locations, and in fact is no longer online. I found the picture on the Wayback Machine.

Irby

Long time ago there was a discussion about oilers like this one with a standpipe in the center. Folks were saying that a wick went from the oil reservoir up and over into the standpipe to draw oil down into the bearing, and sort of meter it also. In fact, Jim himself posted a picture of an example shown below. I wonder if the oiler for the Stark #4 should really have such a wick in it? I guess the far end would run all the way down and touch the spindle. A question for some more Stark #4 guys...

When Jim says "A better photo of how a wick-fed oiler is constructed:", this is the picture he is talking about:

The thread was here:

Antique brass oiler question

But some of the pictures are no longer available because the Metalworking Dropbox where they resided has changed locations, and in fact is no longer online. I found the picture on the Wayback Machine.

Irby