Steady Rest Adjusters Sticking - help needed

I have a telescoping steady that needs some TLC. The knurled adjusters get sticky and can't be used beyond a certain OD. I wanted to take it apart for a cleaning and see what is binding on the threads but it is really put together! Before I use too much force I figured I better ask first.

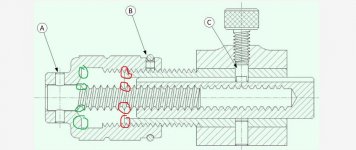

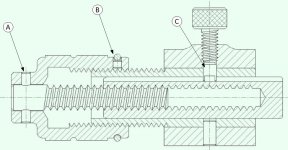

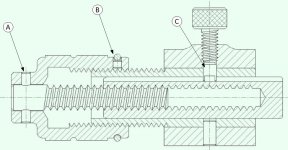

I found this cross section diagram in here that is for a 10K lathe steady. Can I assume the 16 is the same?

Do I punch out the pin "A" and pull the Screw and Finger out as one? I gave the pin a few love taps to free it but no luck and before I go cro-mag on it here I am.

What is the purpose of "B"? I took the retaining ring off but couldn't extract the key but then when I found this x-section I couldn't understand the purpose.

Thanks for any help with this I need the steady for the next step of my collet nut!

I have a telescoping steady that needs some TLC. The knurled adjusters get sticky and can't be used beyond a certain OD. I wanted to take it apart for a cleaning and see what is binding on the threads but it is really put together! Before I use too much force I figured I better ask first.

I found this cross section diagram in here that is for a 10K lathe steady. Can I assume the 16 is the same?

Do I punch out the pin "A" and pull the Screw and Finger out as one? I gave the pin a few love taps to free it but no luck and before I go cro-mag on it here I am.

What is the purpose of "B"? I took the retaining ring off but couldn't extract the key but then when I found this x-section I couldn't understand the purpose.

Thanks for any help with this I need the steady for the next step of my collet nut!

Last edited: