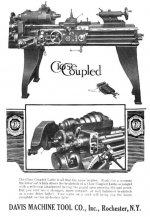

Hello everybody...I have an old 1914 14" Davis Lathe from Rochester Ny...I need to know if anyone can help me out with a few things any info and knowledge will be greatly apreciated...First thing is the taper on the tailstock...3MT is too small and 4MT is too big...I took the dead center and measured it and looked at the chart on this site and my guess is it is a jarno taper...It's fatter than a morse taper...the measurements are 3" long from the bottom to where it stops in the ram and 3/4 bottom and 1"top where it stops in the ram my guess it is a #8 jarno taper...I think but not sureThey call it a close coupled lathe by Davis Machine and Tool Co...Most of them Davis Lathes are stamped WP Davis but this one is just Davis...Any info or anything on this Lathe would be very helpfull...Thanks ahead of time for your help...I will post other questons i have on this Davis Lathe in a seperate post...Another thing is this Lathe is all there and all original not missing anything...I know not to leave the T handle in the chuck I have the machine disconnected from the power

Attachments

Last edited: