michaelf1988

Plastic

- Joined

- Apr 21, 2019

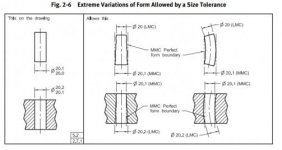

I'm going to try and keep this question as simple as possible. Let's say you have a plate to be machined and your blueprint says the thickness of the plate should be .5000-.5006 for example. What EXACTLY does this mean? Obviously in a perfect world the plate would be like two ideal planes separated .5003 apart. But we don't live in a perfect world and the plate will have warp, low and high points i.e. the usual, however small, variation. I've read things online about the Taylor Principle, Enveloping Principle, 1st Principle whatever you want to call it. It says a feature must be "of perfect form at MMC and any deviation from MMC there is an equal deviation in form allowed." But what exactly does this mean? I get that it is required the plate fits inside an ideal gauge of two plates .5006 apart, but what else is required? Reference to Machinery's Handbook, (ASME) Y14.5-2009 or something official would be helpful. Do both sides of the plate have to be flat to within .0006 and parallel to the opposite side to within .0006 so no two points on the 3D surface deviate outside the .5000-.50006 range, or does the tolerance only apply to the thickness of opposed points, or exactly how does it work?