implmex

Diamond

- Joined

- Jun 23, 2002

- Location

- Vancouver BC Canada

Hi All:

I have another tiny turning project.

This one is tricky because there's so little to hang onto.

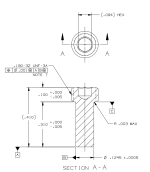

Here's a picture:

The thread is M1.6 x 0.35 and there is a hex in the end (0.028" across the flats 0.75 mm deep)

So I pondered two options:

The first was to turn the pin and single point the thread, then cut off and flip the part and sinker EDM the hex in.

Burning a little hex like this is a bit of a pain, but it can be done if you are willing to spend enough time on it, making a trode, setting it up and letting it noodle away.

The other was to buy 5 mm long M1.6 setscrews and turn down the non-hexed end to get my pin.

I chose the latter, and I eventually got it to work, but it's a bit of a fiddle.

The length of the threaded bit is 1.2 mm, so hanging onto it without wrecking it was tricky and I couldn't turn it very aggressively so a single pin takes almost an hour to make.

(0.001" DOC and many many passes)

I ended up having to make a hardened collet I could squeeze in the Sherline 4 jaw chuck...the brass one I made first didn't survive a single pin before it let go and took out a tool tip and a pair of underwear.

The successful collet was A-2 at 63 RC and it's holding up well.

These were turned on a manual lathe (One of those who's name we dare not speak here)

If you had the gear to do it either of those ways, which would you pick?

Would you maybe find a third way?

Would you have the balls to try to wobble broach the hex? (material can be 17-4 PH or 4140 HTSR)

The hex is just for an Allen key

There's a total of 8 pins to make in two different lengths.

You have to get the pin diameter (1mm ) within a few tenths...it needs to run nicely in a 1 mm reamed hole in 660 bronze.

I turned them to 0.0398" diameter and then polished them in with a mylar abrasive strip ( for finishing dental white fillings) under the scope.

Cheers

Marcus

www.implant-mechanix.com

www.vancouverwireedm.com

I have another tiny turning project.

This one is tricky because there's so little to hang onto.

Here's a picture:

The thread is M1.6 x 0.35 and there is a hex in the end (0.028" across the flats 0.75 mm deep)

So I pondered two options:

The first was to turn the pin and single point the thread, then cut off and flip the part and sinker EDM the hex in.

Burning a little hex like this is a bit of a pain, but it can be done if you are willing to spend enough time on it, making a trode, setting it up and letting it noodle away.

The other was to buy 5 mm long M1.6 setscrews and turn down the non-hexed end to get my pin.

I chose the latter, and I eventually got it to work, but it's a bit of a fiddle.

The length of the threaded bit is 1.2 mm, so hanging onto it without wrecking it was tricky and I couldn't turn it very aggressively so a single pin takes almost an hour to make.

(0.001" DOC and many many passes)

I ended up having to make a hardened collet I could squeeze in the Sherline 4 jaw chuck...the brass one I made first didn't survive a single pin before it let go and took out a tool tip and a pair of underwear.

The successful collet was A-2 at 63 RC and it's holding up well.

These were turned on a manual lathe (One of those who's name we dare not speak here)

If you had the gear to do it either of those ways, which would you pick?

Would you maybe find a third way?

Would you have the balls to try to wobble broach the hex? (material can be 17-4 PH or 4140 HTSR)

The hex is just for an Allen key

There's a total of 8 pins to make in two different lengths.

You have to get the pin diameter (1mm ) within a few tenths...it needs to run nicely in a 1 mm reamed hole in 660 bronze.

I turned them to 0.0398" diameter and then polished them in with a mylar abrasive strip ( for finishing dental white fillings) under the scope.

Cheers

Marcus

www.implant-mechanix.com

www.vancouverwireedm.com