Hello everyone,

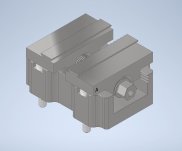

I am working on developing a smaller form factor vise (somewhat based on the Xian Dian mini vise). I wanted to share my progress so far and make sure that I am on the right track with the improvements that I am making. Hoping to get into production soon. Any input and advise would be greatly appreciated.

Improvements made:

- Vise Jaw redesign for built in dovetail (only necessary to use dovetail if parts need it, jaws have teeth that have very good gripping strength)

- Shorter height and lighter weight design (especially good for applications such as use on smaller rotary as well as high density work holding)

- Top Down mounting option

Vise Technical Info:

- 54mm wide x 75mm length x 36.5mm height

- weight of around 0.75kg (1.65lbs)

Please let me know what you think.

Since everyone will be asking, aiming for $249-$299 for single vise and $1199-$1499 for 4X rotary version (quantity discounts will be available)

Thank you!

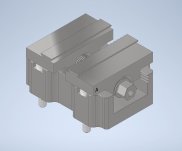

I am working on developing a smaller form factor vise (somewhat based on the Xian Dian mini vise). I wanted to share my progress so far and make sure that I am on the right track with the improvements that I am making. Hoping to get into production soon. Any input and advise would be greatly appreciated.

Improvements made:

- Vise Jaw redesign for built in dovetail (only necessary to use dovetail if parts need it, jaws have teeth that have very good gripping strength)

- Shorter height and lighter weight design (especially good for applications such as use on smaller rotary as well as high density work holding)

- Top Down mounting option

Vise Technical Info:

- 54mm wide x 75mm length x 36.5mm height

- weight of around 0.75kg (1.65lbs)

Please let me know what you think.

Since everyone will be asking, aiming for $249-$299 for single vise and $1199-$1499 for 4X rotary version (quantity discounts will be available)

Thank you!