Cal Haines

Diamond

- Joined

- Sep 19, 2002

- Location

- Tucson, AZ

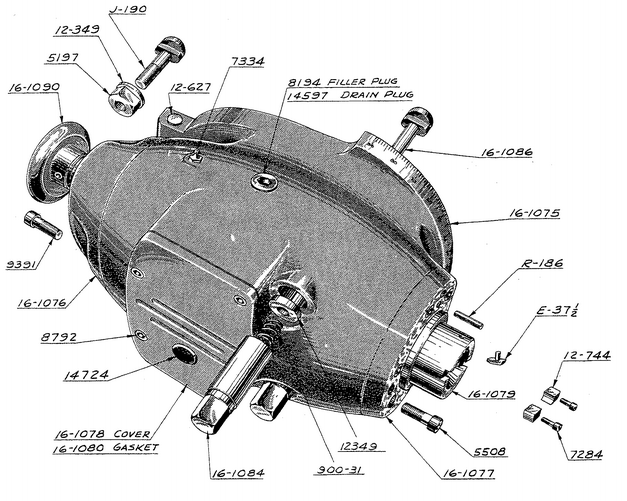

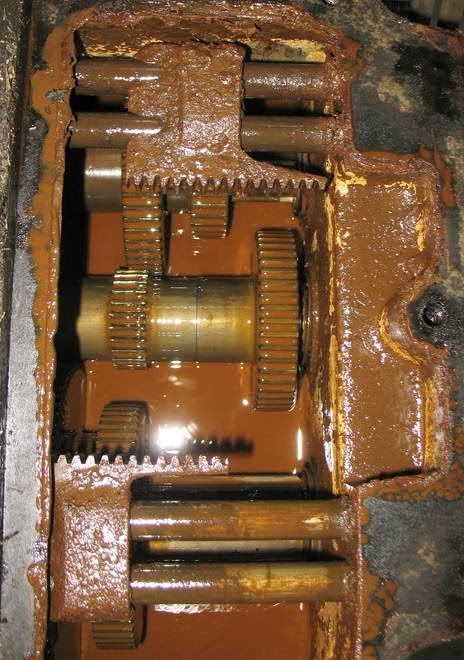

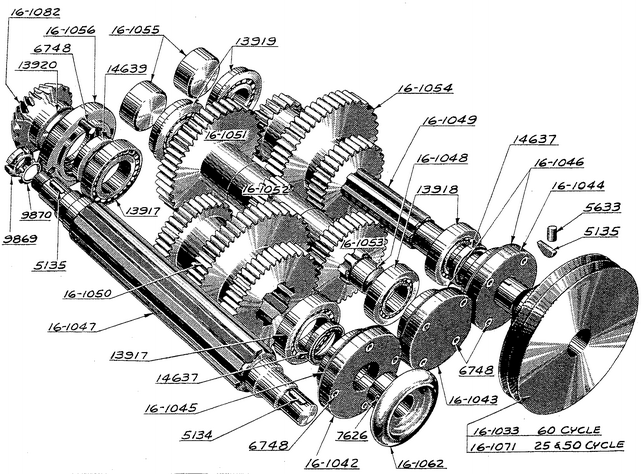

My Van Norman No. 16 mill has been waiting for its turn and I have finally gotten started on the rebuild. The bearings in the gearbox and cutter-head are shot and it's clear that I need to go through the table and most of the components in the knee before the old beast is ready for service.

Before I spend a lot of time posting and take up a space on the server, I want to make sure that there is interest in the subject. I'm planning on an illustrated, step-by-step series as I go through the machine, along the lines of Harry Beckley's epic posts over in the Monarch forum. I'll try to make it interesting for anyone interested in machine tool repair.

So far I have the gearbox torn apart and I would have liked to have known at the start what I have learned so far. Maybe I can leave something here so that the next guy will have a leg up.

So, who wants to play along?

Cal

Before I spend a lot of time posting and take up a space on the server, I want to make sure that there is interest in the subject. I'm planning on an illustrated, step-by-step series as I go through the machine, along the lines of Harry Beckley's epic posts over in the Monarch forum. I'll try to make it interesting for anyone interested in machine tool repair.

So far I have the gearbox torn apart and I would have liked to have known at the start what I have learned so far. Maybe I can leave something here so that the next guy will have a leg up.

So, who wants to play along?

Cal