scrapNcrash

Plastic

- Joined

- Feb 19, 2023

I am a small shop owner doing job shop work and production runs. We run into the problem of remembering how we ran jobs because each operations will have a separate programming file. It’s a pain to click through each programming file to remember how we ran a job and we’d like to have one router to quickly tell us how we ran it. Also, I am growing my shop so our team is expected to go to 10 people. Right now, I’m having to chase down every order in the shop and instruct the employee what’s needing to be done next on each one. From the dozens of threads I’ve read on here—every machinist seems to hate routers. I am both a machinist, programmer, and shop owner so I’m having a pain focusing on my job and keep other people busy at their workstations because they’re constantly having to be told what to do. So for that, we would like to create detailed work instructions for each step of the process. I have experience doing this as I worked as a process engineer for a large machine shop and all I did was create routers on how parts were to be made from scratch to finish. Now the question is, is there a template, excel sheet, access database we can use. We have a bid from JobBoss/E2 which have merged now. That may be our end game but for now I just want to create detailed job routers/instructions so I don’t have to chase jobs down and tell guys what to do next on a job. I’m small enough to where scheduling isn’t an issue—I can just tell the guys-“we are running this then that then that” but I’m large enough to where I can’t handle giving step by step instructions to each machinist/operator.

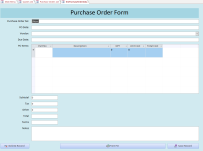

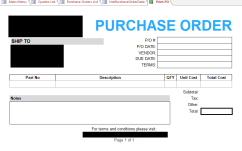

My initial plan is to create a Microsoft Access database to create this relational database to track customers, PO’s, SO’s, and WO’s. I can then relate part numbers to routing sequences. Then when a WO is created for a PN, it can copy over routing sequences onto a report. Then I can print the report. Am I overlooking anything. Anyone having this same problem. I understand the machinists in this community REALLY hate job travelers but from a management POV, I need a way to communicate with multiple people without running around with my head cutoff. Open to all ideas and clean sheet ideas if I’m thinking of this the wrong way. Thanks

My initial plan is to create a Microsoft Access database to create this relational database to track customers, PO’s, SO’s, and WO’s. I can then relate part numbers to routing sequences. Then when a WO is created for a PN, it can copy over routing sequences onto a report. Then I can print the report. Am I overlooking anything. Anyone having this same problem. I understand the machinists in this community REALLY hate job travelers but from a management POV, I need a way to communicate with multiple people without running around with my head cutoff. Open to all ideas and clean sheet ideas if I’m thinking of this the wrong way. Thanks