stephen thomas

Diamond

- Joined

- Jun 3, 2001

I won't say i am a "convert", but recently did some resawing with the popular 1/2" blades as opposed to my usual 1" or 1-1/4" wide bands. The reason was I had a bunch of NOS 1/2" bands bought on eBay probably 10 years ago and never used except the conventional tooth ones for contour sawing, and for my pool stick joints due to the slightly smoother kerf.

Subject to recent discussions here on PM I dug in the back and dusted off the pile of hook tooth bands and decided to try one since all my large bands are dull, and have been already re-sharpened several times each. The boxes say 4T Reg Skip .025. But they are very definitely hook tooth profile. This is the saw.

I set the saw up carefully and did some experiments. The thin band cut narrower stock with less waste due to thinner kerf. But in wider stock (over say 6" wide) it was a toss-up. The thin band deflected more in the kerf and negated the savings by about the same amount in requiring sawing a little thicker to clean up to the same finish thickness. But my wide bands were dull & hard to feed, as mentioned, and the 1/2" seemed to have some promise. So I switched back to the 1/2", and optimized the saw as much as possible for that.

This fence has a long crown in it lengthwise, to facilitate steering. (If laid on a flat surface, the plywood face is straight across edge-to-edge but has about 3/64" - 1/16" crown lengthwise.)

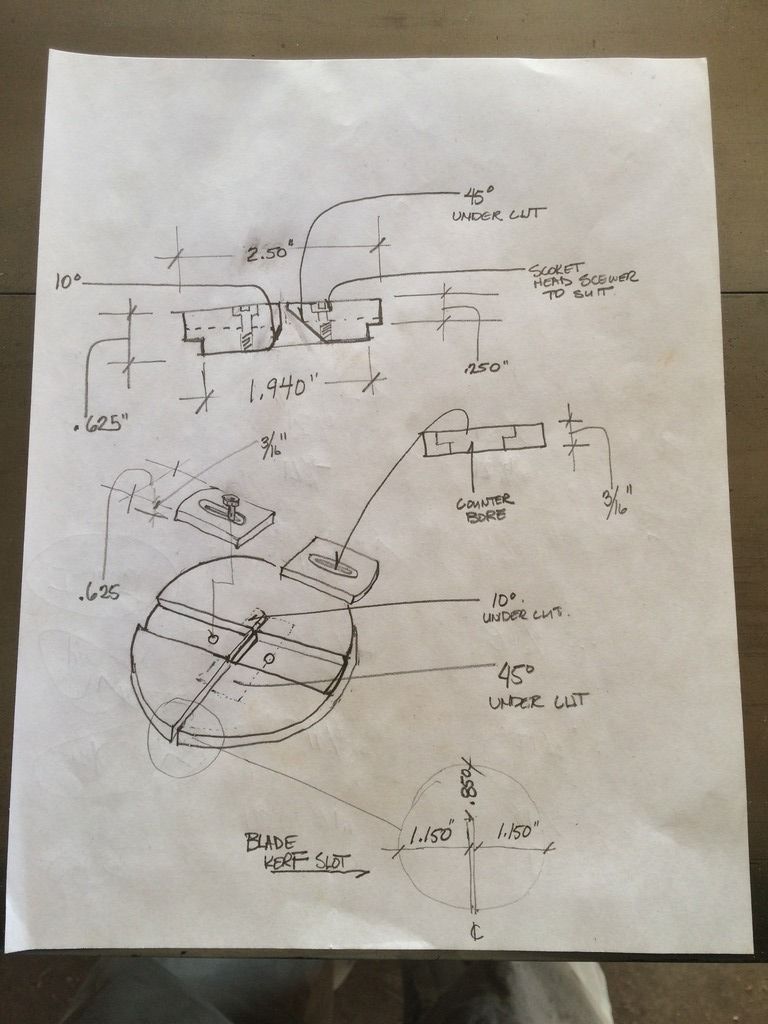

One of the things I was forced to do is something put off for decades.

The top jaws of the lower guide was about 3" below the table, so the table can be tilted, but a bit more than necessary even for that. The bracket has also never been satisfactory. I made a new bracket/"dogbone" out of heavier steel, and moved the guides up 2.5". This might not seem like much, but as a percentage it is huge, and getting the jaws near where the band exits the kerf even more important over-all. Some day I'll make a set up like Richard has, with the bottom guide right in a sub-table where the band directly exits the bottom of the work.

My method for sawing veneer is probably a little different than I have read from others.

For very thin veneers, such as feature/face stock, it is pointless to saw off faces from a cupped or significantly warped blank. Either one has to saw too many veneers too thickly to allow clean-up, or one loses veneers in the process as the wood cups or humps. So my first step is to be sure the side of the blank with the long bow in it, is flat edge to edge. I do not worry about the other side at this point, though it usually gets a pass over the jointer as well to remove the most stressed surface. (the pieces sawn for this project were unfortunately received skip dressed to 15/16, reason they look surfaced)

I actually "prefer" a slight long bow since it permits steering the board on the saw.

I mark one edge of the board strongly. Several lines, in case some get splintered or worn off. The angled lines make it possible to quickly match the sequence after all the veneers are sanded and finished. I'm usually sawing more than one board in a process like this, so not only do the individual veneers fall out of sequence, they get mixed with with 25 or 30 others from other boards. Usually length x width allows a quick board (flitch) re-sort. then the lines on the edge make it easier to sort for sequence.

smt

Subject to recent discussions here on PM I dug in the back and dusted off the pile of hook tooth bands and decided to try one since all my large bands are dull, and have been already re-sharpened several times each. The boxes say 4T Reg Skip .025. But they are very definitely hook tooth profile. This is the saw.

I set the saw up carefully and did some experiments. The thin band cut narrower stock with less waste due to thinner kerf. But in wider stock (over say 6" wide) it was a toss-up. The thin band deflected more in the kerf and negated the savings by about the same amount in requiring sawing a little thicker to clean up to the same finish thickness. But my wide bands were dull & hard to feed, as mentioned, and the 1/2" seemed to have some promise. So I switched back to the 1/2", and optimized the saw as much as possible for that.

This fence has a long crown in it lengthwise, to facilitate steering. (If laid on a flat surface, the plywood face is straight across edge-to-edge but has about 3/64" - 1/16" crown lengthwise.)

One of the things I was forced to do is something put off for decades.

The top jaws of the lower guide was about 3" below the table, so the table can be tilted, but a bit more than necessary even for that. The bracket has also never been satisfactory. I made a new bracket/"dogbone" out of heavier steel, and moved the guides up 2.5". This might not seem like much, but as a percentage it is huge, and getting the jaws near where the band exits the kerf even more important over-all. Some day I'll make a set up like Richard has, with the bottom guide right in a sub-table where the band directly exits the bottom of the work.

My method for sawing veneer is probably a little different than I have read from others.

For very thin veneers, such as feature/face stock, it is pointless to saw off faces from a cupped or significantly warped blank. Either one has to saw too many veneers too thickly to allow clean-up, or one loses veneers in the process as the wood cups or humps. So my first step is to be sure the side of the blank with the long bow in it, is flat edge to edge. I do not worry about the other side at this point, though it usually gets a pass over the jointer as well to remove the most stressed surface. (the pieces sawn for this project were unfortunately received skip dressed to 15/16, reason they look surfaced)

I actually "prefer" a slight long bow since it permits steering the board on the saw.

I mark one edge of the board strongly. Several lines, in case some get splintered or worn off. The angled lines make it possible to quickly match the sequence after all the veneers are sanded and finished. I'm usually sawing more than one board in a process like this, so not only do the individual veneers fall out of sequence, they get mixed with with 25 or 30 others from other boards. Usually length x width allows a quick board (flitch) re-sort. then the lines on the edge make it easier to sort for sequence.

smt