andrewmawson

Hot Rolled

- Joined

- Jan 9, 2003

- Location

- UK

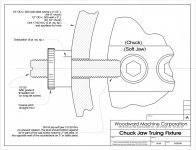

I went to bore some soft jaws today and had an issue that currently has me stumped. I need to bore full depth for bar stock to pass through, so cannot use a stepped plug or whatever to the rear of the jaws, so reach for my Jaw Ring (see picture).

Now I've used this satisfactorily before, but today, adjusting it to space the jaws approximately where I want them under compression, the chuck closing force just moves the sliding pegs down the cam shaped grooves reverting to chuck closed. Obviously there is insufficient friction between the sliding pegs and the cam grooves. So experimenting I switched the chuck to low clamping force - same happens - argh !! Then I reduced the hydraulic pressure for 'low clamp' as low as I could and still same symptoms. (second argh !!! )

Now I can make up a plate with three pegs welded on in about the right place with a central hole for my boring bar, but why is this suddenly happening. How can I increase the friction in the slots to stop the pegs sliding round back to closed ???

Anyone else had this issue?

Now I've used this satisfactorily before, but today, adjusting it to space the jaws approximately where I want them under compression, the chuck closing force just moves the sliding pegs down the cam shaped grooves reverting to chuck closed. Obviously there is insufficient friction between the sliding pegs and the cam grooves. So experimenting I switched the chuck to low clamping force - same happens - argh !! Then I reduced the hydraulic pressure for 'low clamp' as low as I could and still same symptoms. (second argh !!! )

Now I can make up a plate with three pegs welded on in about the right place with a central hole for my boring bar, but why is this suddenly happening. How can I increase the friction in the slots to stop the pegs sliding round back to closed ???

Anyone else had this issue?