David_M

Hot Rolled

- Joined

- Sep 30, 2014

- Location

- Midway, GA, USA

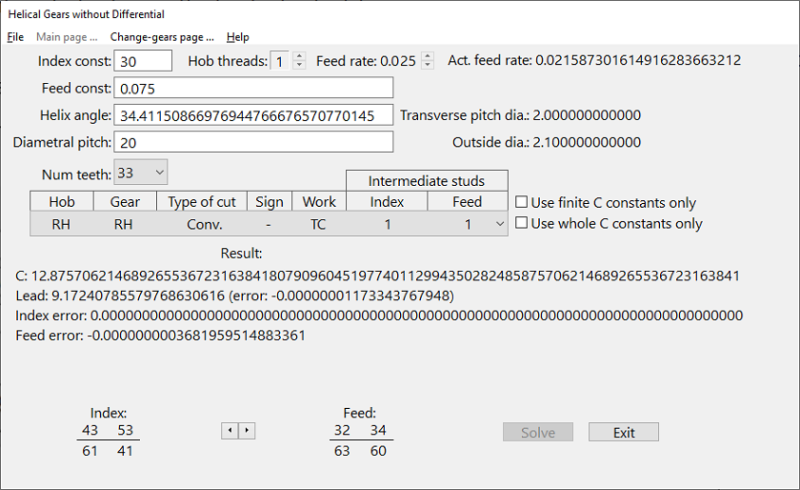

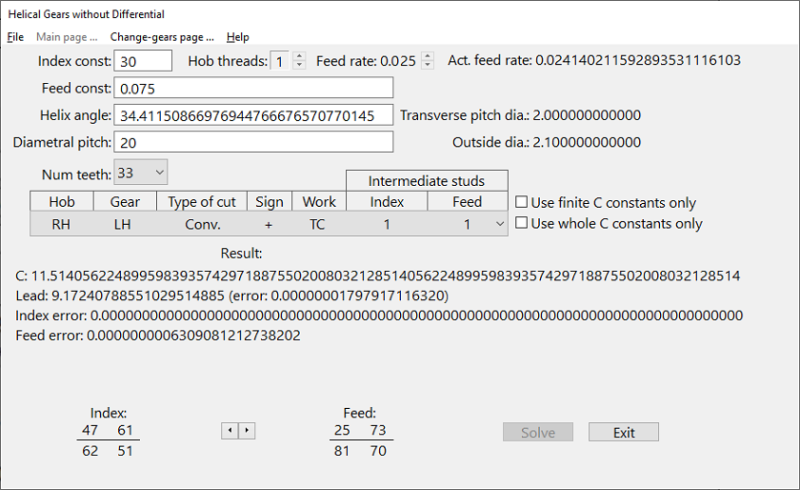

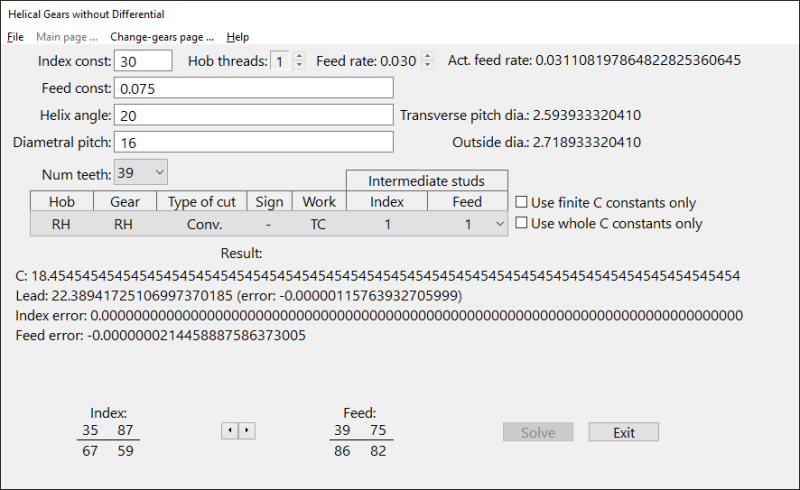

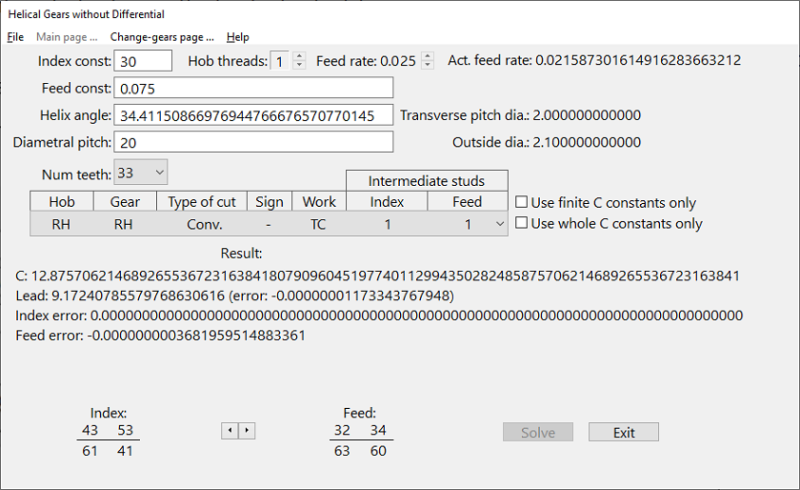

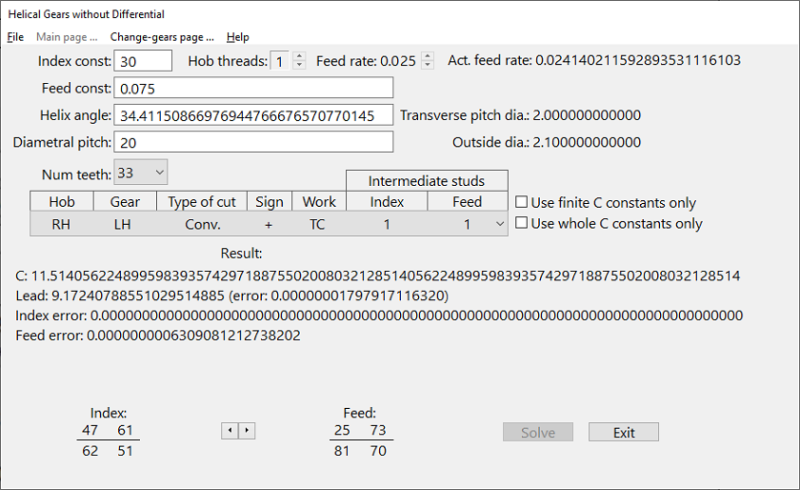

I would like to purchase two helical gears from a forum member. These need to be hobbed on a gear hobber that uses manual change gears.

Below shows the specifications. I am interested in having the leads checked, too.

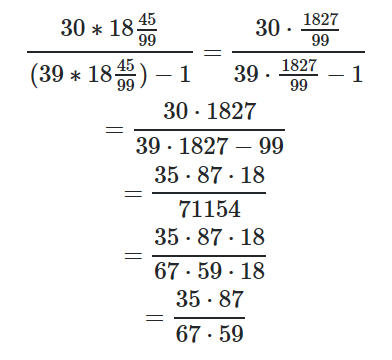

I want to specify what change gears to use based on the gear cutter's index and feed constants (it's a test). These could be cut out of 360 brass or anything that machines easily and maintains its shape (not nylon).

Below shows the specifications. I am interested in having the leads checked, too.

I want to specify what change gears to use based on the gear cutter's index and feed constants (it's a test). These could be cut out of 360 brass or anything that machines easily and maintains its shape (not nylon).