Skrueball, Welcome to PM.

Two Myers lathes in two days!

Nice clean up on the lathe. That is one good looking gear chart, new black paint?

Myers did not date their catalogs so things like guards for the back gears, design changes to the apron, and finish help approximate years of manufacture.

The gear chart on the back gear cover is a better location than on the leg. Don't know if that was a Myers' mod or not.

The apron is similar to that on the 10" lathe with respect to the cross feed engagement. Prior method for the 11" was a push-pull pinion gear engagement as shown in post #2.

The apron front face on the early 11" lathes was left 'as cast'. Later the face was machined to a flat finish and post war returned to the 'as cast' finish.

The spindle journals are oiled by a drip oiler / gravity feed oiler. Myers only supplied a machined plug for the top bearing shell.

The rear spindle bearing is a sleeve cut on one side only. The body of the sleeve should fit onto a locating pin. The front spindle bearing is a typical top and bottom shell.

Photos-Images:

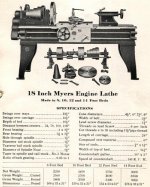

Specs from the catalog, Follow and Steady rest, Shelf and Gear Train, and the Apron showing the original knob for cross feed engagement.

The black lathe is not mine. The lathes I have use the push-pull pinion for crossfeed engagement.

Thanks for posting your lathe,

John