lapoole

Plastic

- Joined

- Jan 13, 2020

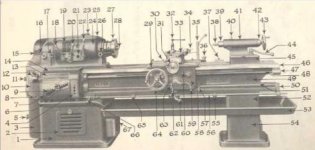

Inspection/assessment checklist attached below, along with diagram it refers to.

I'll update this as new info becomes available. Feedback & suggestions are welcome; I'm a beginner.

View attachment AssessmentChecklist.txt

I'll update this as new info becomes available. Feedback & suggestions are welcome; I'm a beginner.

View attachment AssessmentChecklist.txt