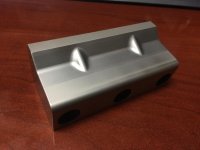

I'm working on a design for a progressive tool for one of our products and my soft try-out tool leaves a couple bends shy of the ideal 90 degrees. I know there's ways to overbend the material, but this is new stuff for me so I'm trying to keep it simple.

I have used darts and ribs in simple press brake parts before and they do wonders for stiffness and seem to help consistency. I'm thinking adding darts in these features, the darts would be formed after the bends are made in the same hit, would help push material around in the corner and contribute to the part coming out nearer a true 90 than the 85 or so I'm getting now.

Not sure it matters, but this is 11 gauge mild steel. .125 inside radius. length of bend is about 1.25" times two. Thinking .250 pins for darts?

Any input?

I have used darts and ribs in simple press brake parts before and they do wonders for stiffness and seem to help consistency. I'm thinking adding darts in these features, the darts would be formed after the bends are made in the same hit, would help push material around in the corner and contribute to the part coming out nearer a true 90 than the 85 or so I'm getting now.

Not sure it matters, but this is 11 gauge mild steel. .125 inside radius. length of bend is about 1.25" times two. Thinking .250 pins for darts?

Any input?